RELATED WAFER PROCESSING TEMPORARY BONDING FILMS AND SPIN COATINGS:

- Wafer-Substrate Thinning Spin Coatings and Films

- Wafer Grinding Tapes with and without Buffer Layer

- High Vacuum Dry Etching Thermal Interface Materials

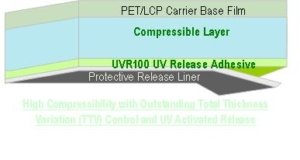

Compressible and conformable layer coupling with a thin UV releasing pressure sensitive layer enables the flip-chip bumps on wafer and solder balls on the substrate boards to be planarized for backgrinding

High Vacuum Dry Etching Temporary Bonding Thermal Adhesives

- High Thermal Grease-Gel Bonding in High Vacuum Etching Chamber

- High Thermal Bonding Pad for High Vacuum Etching Chamber

| PROPERTY/PARAMETER | CGR7016/CGR7018 |

| Bond Strength (Operation) | Capillary, 10 psi shear |

| Removal (Method) | IPA with/without Heat |

| Vacuum Capability | 10−12 pressure |

| Chemical & Etching Tolerance | Proven, Outstanding |

| Dielectric Strength (Volts/mil) | >250 |

| Device Push-off Strength (psi) | >10 |

| Density (gm/cc) | 2.5 |

| Thermal Conductivity | > 4.0 W/m-°C |

| Maximum Continuous Operation Temp. (°C) | > 150 |

| Electrical Resistivity | >10¹⁴ ohm-cm |

Properties of AIT Back-Grinding & Thinning “WAX” and Tapes

- Spin Coating IPA Soluble Wax and Film for Wafer and Substrate Thinning

- Back Grinding for Wafer with Flip-Chip Bumps and Substrate with Solder Bumps

| PARAMETER | BGL-7090, BGF-7090 | BGL-7160, BGF-7160 | BG-Buffer-Adhesive |

| Operational Temperature Capability |

| ||

| Thickness of Temporary Bonding Layer |

| ||

| Die-Shear Bond Strength |

| ||

| Operational Temperature Capability |

| ||

| De-Bonding Temperature and Mechanism |

| ||

| Cleaning Media | Iso-propanol (IPA) | Iso-propanol (IPA) | Iso-propanol (IPA) |

| Water Jet Resistance | Outstanding | Outstanding | Outstanding |

Temporary bonding wax and film are one of the lowest cost and effective means in thinning substrates and wafers

Please click here to watch our video on Wafer Processing Film and Spin Coating Adhesives

AIT application engineering, sales, chemists and material scientists are ready to serve your special needs and applications. Please inform us of your requirements using the contact / application assistance page:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308