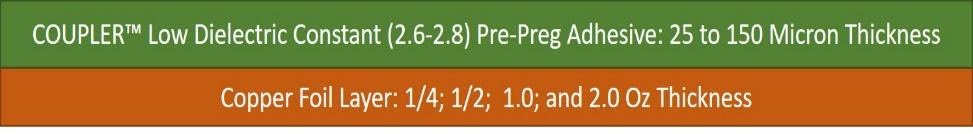

COUPLER™ PREPREG and ADHESIVE FILM for MULTILAYER FLEX CIRCUIT to enable more versatile and high-speed flexible electronics

Multilayer flex circuits

More complex flex circuits may need more than two layers of conductors to form the multilayer flex circuit. Interlayer interconnections are often made with plated through holes or other means depending on the features and applications.

The thickness of copper layers may or may not be the same depending on the flexible circuit’s functional requirements. The thickness of the dielectric may also be different for different flexibility and insulation requirements.

For the multilayer build-up, the additional layers of copper-clad substrates are typically on prepreg dielectric (B-staged or yet to be cured dielectric adhesive). They are cut into sizes and shapes that are used for multilayer build-up. The layering lamination is done under pressure and heat that are prepreg material dependent.

COUPER™ prepreg differs from traditional flexible circuit substrates using acrylic-type adhesive. The dielectric is a specialty AIT molecularly engineered B-staged dielectric that when cured is exactly the same as the copper-clad substrate. In addition, the lamination pressure required is less than 15 psi and at a temperature from 125-175°C with a controlled melt-flow using a temperature-controlled calendaring process. The instant melt-flow calendaring process can be done in continuous processing with inline post-curing for dramatically higher productivity in comparison to traditional vacuum hot-press processing.

Rigid-flex circuits and flex circuit with stiffener

Rigid-flex circuits are a hybrid construction flex circuit consisting of rigid and flexible substrates which are laminated together into a single structure. Rigid-flex boards are normally multilayer structures.

Rigid-flex circuits differ from flexible circuits with a stiffener. In this case, a flexible circuit is locally bonded on a stiffener to allow components mounting without suffering from flexing and bending stresses.

In the case of COUPER™ prepreg, AIT engineered the B-staged dielectric that can be laminated with less than 15 psi and can melt-flow at 150°C easily using a heat-calendar process to allow for much higher productivity than vacuum hot-press processing.

To provide additional flexibility, AIT also provides COUPLER prepreg without copper-clad. This dielectric adhesive layer once cured also has the same material characteristics as the copper-clad dielectric. The use of this prepreg film adhesive allows flexibility in multilayer and rigid-flex circuit build-up.

COUPLER™ laminates and multilayer flexible circuits built with compatible prepreg of the same dielectric are compatible with all traditional flexible circuit and FR4 circuit manufacturing.

COUPLER™ SINGLE-CLAD Prepreg and Dielectric Adhesive Prepreg

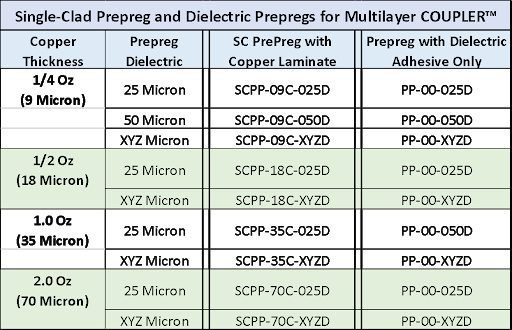

The following table represents the different variations of COUPLER™ prepregs with and without copper-clad.

Typical copper-clad thicknesses start with 1/4oz to 2 oz. The thinner and thicker copper thickness will required custom configurations.

The dielectric adhesive layers are typically 25 and 50 microns with other thicknesses available as custom configurations.

Instead of using a lower temperature and lower performance acrylic-coated prepreg, COUPLER™ uses the prepreg adhesive that has identical dielectric properties as in the COUPLER™ laminates. These novel prepregs have the following processing and performance advantages:

- Multi-layer lamination at much lower pressure temperature and time: 10-15 psi at 150-180°C in seconds for melt-bonding using calendaring for unparalleled throughput.

- AIT provides copper-clad prepregs with different thicknesses of copper and dielectric adhesive prepregs without copper, and overlay dielectric adhesives meeting industry standards in high-reliability applications and reliability.

Prepreg Features and Distinctive Properties:

- Outstanding peel and shear bond strength

- High thermal resistance for applications (>180°C, continuous usage) and processing (>290°C for minutes)

- Halogen-free, REACH, and RoHS compliant

- No to Low moisture absorption and outgassing meeting NASA/ISA requirements

- Prepregs are ambiently storable

- Capable of withstanding multilayering laminations with layer limits without any degradation

In the above configurations and availability of single-clad and film adhesive prepregs, XYZ represents the custom thicknesses that are thinner than 25 microns or thicker than 50 microns.