AI Technology (AIT) pioneered the first self-supporting (no glass-mesh) epoxy and cyanate ester B-staged film adhesives in 1980s for semiconductor applications. AIT has since developed film adhesives for different applications from die-attach to flexible circuits. With more molecular engineering, AIT is now ready to provide pilot quantity of build-up film with much more stringent controlled CTE matching 3-D core boards, copper traces and:

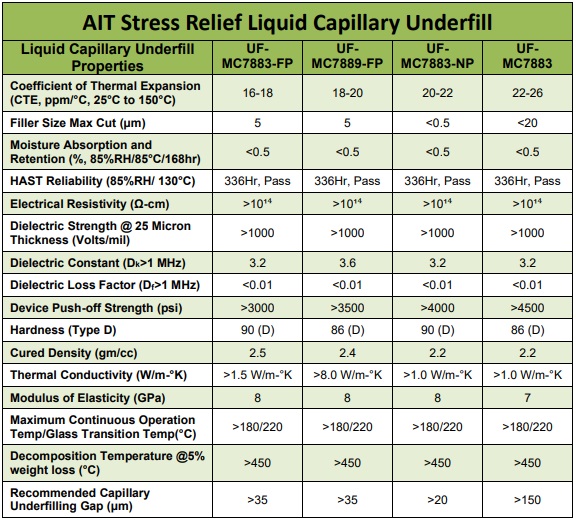

- AIT BUF is molecularly engineered to have the following unparalleled and balanced properties of high Tg with stress absorption along with low moisture absorption and low dielectric Dk and Df for reliability and performance.

- Much lower lamination temperature and pressure for higher productivity.

- The modified cyanate ester based BUF is a proven technology that is now expanded to for use in electronic sheet and liquid molding-encapsulation.

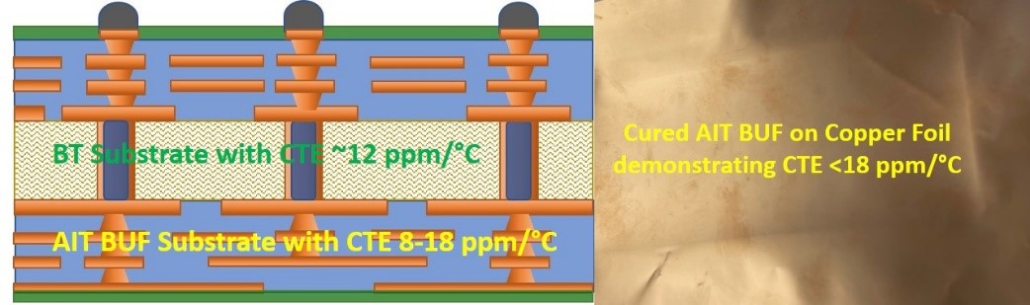

Build-Up Film with 8-18 PPM/°C CTE

New class of CTE controlled build-up prepreg adhesive for 3D and chiplets applications:

- Nano-filler filled with engineered high melt flow and controlled CTE

- Engineered CTE to match copper or HDI core board from 8-18 ppm/°C for build-up flexibility and different applications

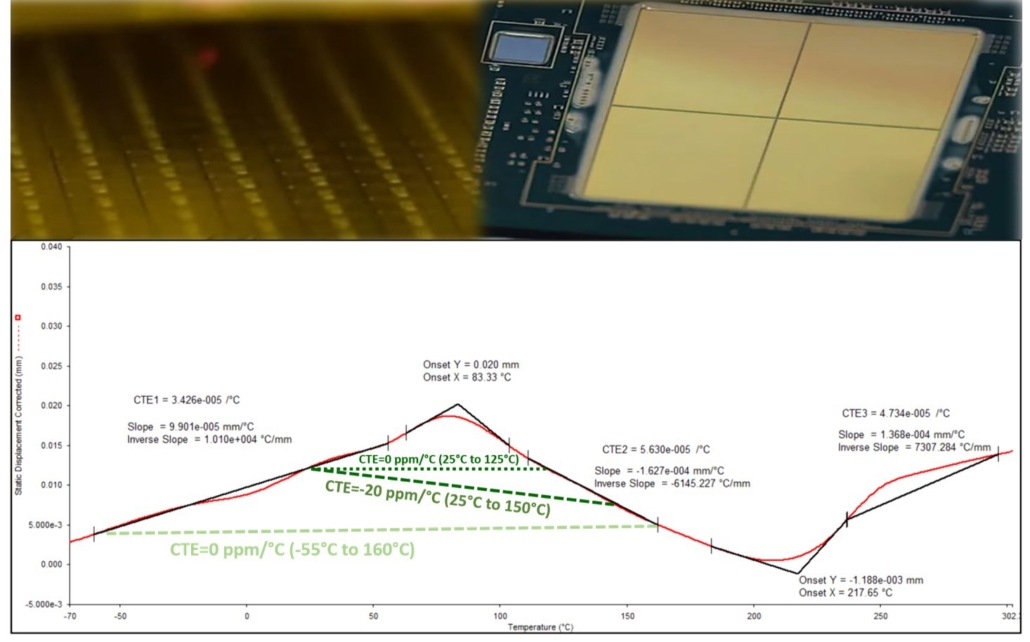

- Molecularly engineered stress-relief high Tg modified cyanate ester

Low Dk and Df Build-Up Films and Beyond

- New class build-up film adhesive technology with low dielectric constant and loss for high-speed circuit performance

- Proven molecularly engineered CTE to match copper for build-up flexibility

- Proven molecularly engineered stress relief High Tg modified cyanate ester technology

- Much lower moisture absorption and retention for reliability and circuit performance