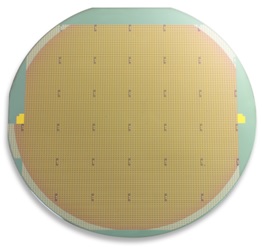

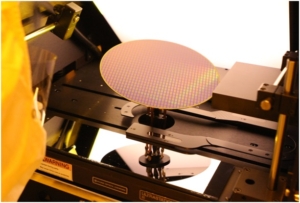

WAFER PROCESSING FILM AND SPIN COATING ADHESIVES THAT ENABLE WIDE PROCESSING WINDOWS:

- 5-80 Micron and Thinner Film That Enables Much Thinner and Exact Wafer Processing

- The Only Non-Polar Adhesive for Stress-Free Temperature Processing Up to 320°C

- Modified Cyanate Ester for High Stress-Free Temperature Processing up to 330°C

- Crystal Clear Transparency for Processing Alignment

Properties of AIT Wafer Processing Adhesives Including 3DTSV:

- First in melt-flow bonding film for 60 micron and thicker for high topography wafer processing

- Short bonding time of seconds at moderate temperature @150°C so as not to induce undue internal stress

- Cured for cross-linked adhesive strength and stability for mechanical wafer grinding thinning

- Molecular thermal stability and compressive strength for 3D processing at temperature of 300-330°C without degradation in bond strength or generating any outgassing to cause voids

| PARAMETER | WPA-TS-320 | WPA-TL-330 |

| Release-Separation Mechanism |

|

|

| Supplied Formats and Bonding |

| |

| Thickness Availability |

| |

| Polymer and Temperature Capability |

|

|

| Separation-Release Temperature and Cleaning |

|

|

| Chemical and Acid-Base Compatibility |

| |

| Etching and Other Processes |

| |

Please click here to watch our video on Wafer Processing Film and Spin Coating Adhesives

AIT application engineering, sales, chemists and material scientists are ready to serve your special needs and applications. Please inform us of your requirements using the contact / application assistance page:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308