Thermal Gap Filling Potting Gel for Cylindrical Cell Packing

Heat generated by individual cylindrical battery cell must be distributed to the thermal-mechanical casing in forming modules and eventually connected to the structural frame and cooling system. There are many choices of possible thermal potting solutions from high-strength thermal potting to thermal greases that have different advantages and disadvantages.

While thermal greases or high-strength thermal potting compounds may be used, AIT engineered a special but proven gel-forming thermal potting compound for the ease of rework and more importantly for the ease of recycling.

- Instead of housing inclusive grinding, costly recovery, and refining, AIT thermal gel solution enables direct layer by layer lower cost recovery during recycling

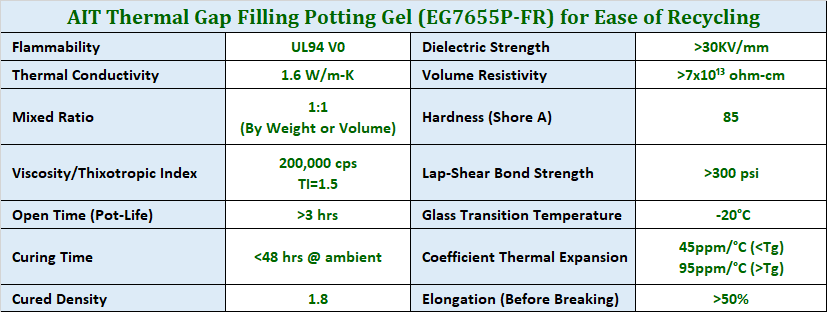

- Gel forming so that the thermal transfer capability is constant and stable even for the highest temperature and low-temperature cycling

- Proven low moisture absorption with intrinsic fire retardancy and self-extinguishing UL 94 V-0 vehicle safety

- The basic extra-flexible epoxy polymer and its molecular structure have more than 30 years of proven history of stability with low moisture absorption

- The high flow potting compound is self-leveling to form void-free thermal transfer interfaces between cells and to the metal case enclosure for hot-spot minimization

- 1:1 by weight or volume and non-critical mix ratio is engineered with long pot-life for ease in manufacturing operation

- The proven low ionic impurities and low moisture absorption potting compound has high dielectric strength and insulation resistance

- The intrinsically self-extinguishing thermal conductive gel ensures safety in large capacity EV battery operation