Wafer Level Cavity Electronic Packaging with Cap Wafer with Pre-Applied Moisture and Corrosive Gases Blocking Adhesive Film

Wafer and panel scale lid-sealing is the cost-effective methods of cavity electronic packaging. Method of dispensing and B-staging the lid-sealing adhesive onto the rims of all caps (lids) on the cap-wafer and cap-panel required special manufacturing techniques for cost-effectiveness. Instead of time-consuming programmable dispensing and B-staging onto all of the lids (caps) on the wafer and panel scale, the unique availability of film adhesive enables the possibility of effective transfer of the adhesive film onto the sealing lid of all of the caps on the wafer and panel and directly.

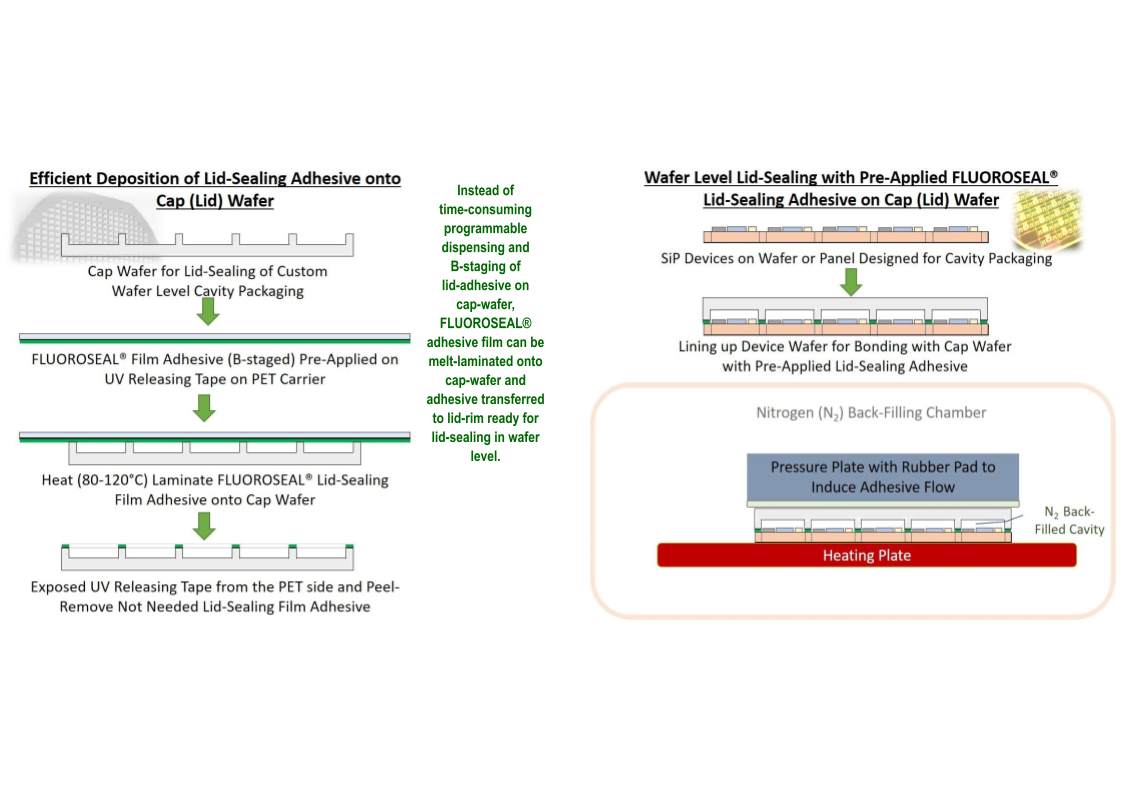

The following is a pictorial representation of the wafer and panel level adhesive deposition and lid-sealing processes:

- FLUOROSEAL® film adhesive (examples: LS-CXP7450 or LS-CXP8450 or LS-TP7150 from AIT) of suitable thickness is first laminated onto suitable UV releasing wafer processing adhesive (examples: WPA-UVR270 or WPA-UVR100).

- The lid-seal adhesive film and wafer processing adhesive combination is used to laminate with heat (at >80-120°C and 10 psi) onto the cap-wafer or cap-panel.

- Expose WAP-UV on the PET side and peel-remove from the cap-wafer or cap-panel to leave only adhesive on the lid.

- Align the cap-wafer or cap-panel with the corresponding wafer or panel and iso-thermally heat laminate (>150°C and 10 psi) to bond together instantly under controlled back-filling inert gases as usual.

- If needed, post-curing can be finished in the air without a controlled N2 backfilling environment.

High Productivity Wafer and Panel Scale Lid-Sealing with Moisture and Corrosive Gases Blocking Lid-Sealing Adhesives:

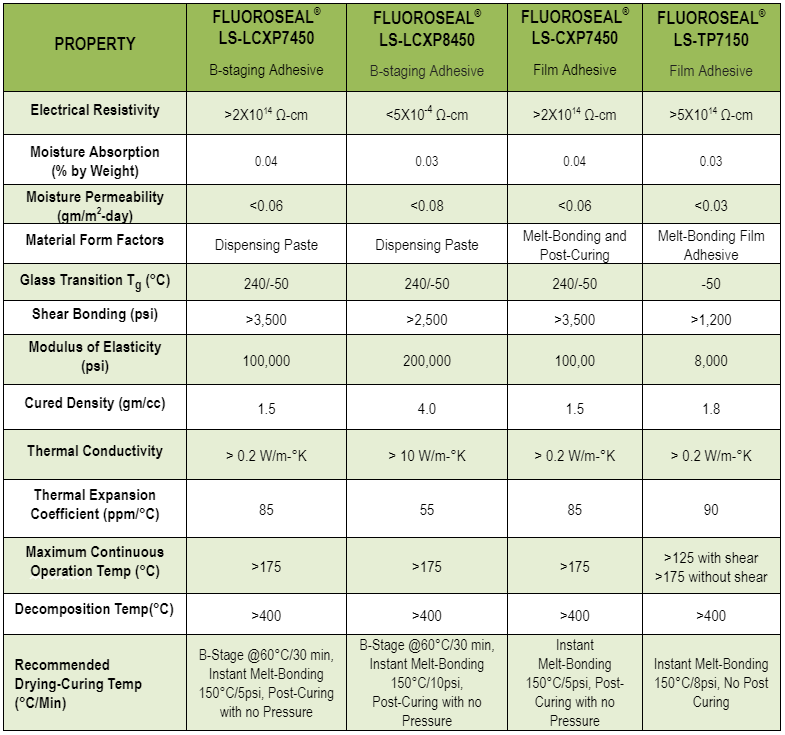

- FLUOROSEAL® lid-sealing adhesives are available in paste and film formats with conductive variations in case EMI shielding is required.

- In comparison to epoxy lid-sealing adhesives, FLUOROSEAL® lid-sealing adhesives are molecularly engineered to have 10-fold less moisture absorption and more than 100-fold lower in moisture and corrosive gases permeability to provide true near-hermetic sealing.

- FLUOROSEAL® lid-sealing adhesives are hydrophobic and unlike most epoxies are intrinsically free of ionic impurities that could reduce circuit reliability.

- FLUOROSEAL® lid-sealing adhesives have outstanding shear-bond strength and high-temperature molecular stability for continuous use >175°C to meet the more stringent automotive electronic devices.

- Engineered molecular structure with low and high Tg molecular components for stress absorption with proven outstanding thermal cycles, shock, and low-temperature exposures.

- Once FLUOROSEAL® lid-sealing paste adhesive is dispensed and B-staged, it can be shipped at ambient and used within 12 months.

- B-staged FLUOROSEAL® lid-sealing adhesive can be instantly melt-bonded and post-cure without applied pressure for high volume inline manufacturing.

The following are outlines of some of these adhesive films that are suitable for the wafer and panel scale lid-sealing process.