DIE ATTACH and THERMAL INTERFACE MATERIALS for CPU, GPU, MEMORY MODULE from LAPTOP and TABLET to MAINFRAME COMPUTER, SUPERCOMPUTER and MULTI-CORE SERVER AND DESKTOP COMPUTER

- High Performance Electro-thermal Die-Attach for High Power CPU and GPU

- Instant Bonding Pressure Sensitive Thermal Tape Adhesive for GPU Module

- Compressible, Conformal Phase-Change Thermal Interface Material (TIM) Pad

PROVEN LOWEST POSSIBLE DIE-ATTACH THERMAL RESISTANCE DIE ATTACH ADHESIVES FOR OVER 20 YEARS:

Die-Attach thermal management is the first and most critical layer of the thermal stacks in a CPU and GPU modules. Highest thermal conductivity with thin and void-free bond-line of the die-attach adhesive is critical in dissipating the heat quickly to the broader module substrate. AIT has more than 20 years of proven records in supporting highest performance super-computers, mainframe computers, servers, desktop, laptop and tablet computer for high performance CPU and GPU modules with it high molecular flexibility and lowest thermal resistance die attach adhesives.

- ME8512 is a popular choice of void-free die attach with low electrical and thermal resistance.

- ME7519-LB is thermally conductive and electrically insulating die-attach adhesive.

- ME7159-CD and ME8456-DA have been the workhorses for the most demanding CPU and GPU bonding of large dies.

- MC7885 and MC8880 for high power applications with temperature operation of 250°C and beyond.

|

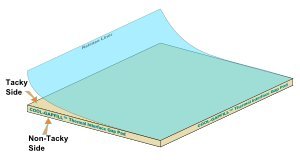

Compressible Phase-Change Thermal Interface Pads

- Compressible and conformal couples with phase change to allow elimination of voids

- Proven for most stringent and including military applications

- Non-silicone and non-contaminating

- US patented innovation

| Thermal Interface Materials for Extreme Power GPU | ||

| FUNCTION | AIT PART # | THERMAL, ELECTRICAL AND OTHER RELEVANT PROPERTIES |

| Compressible Phase-Change | COOL-SILVER™ PAD CPR8850-LB |

|

| Compressible Phase-Change | COOL-SILVER™ G3 PAD |

|

| Compressible Phase-Change | COOL-PAD™ CPR7159-LB |

|

| Compressible Phase-Change | COOL-PAD™ CPR7155-LB |

|

| Gap-Filling Thermal Pad | COOL-GAPFILL™ DT |

|

| Gap-Filling Thermal Pad | COOL-GAPFILL™ TT |

|

| Thermal Gel | COOL-SILVER™ G3 Gel |

|

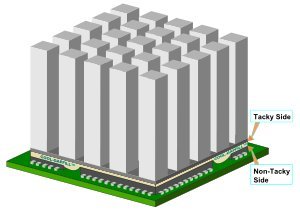

Compressible Thermal Gap Pad Thermal Interface

- Compressible and conformal

- Proven for large area requiring thermal filling into height gaps of different components

- Ideal for large area module to device enclosure

- Proven and used for most critical thermal challenges with military grade reliability

- Non-silicone and non-contaminating

- Available with different thickness with one-side or both side pressure sensitive

Thermal Interface for the Ever More Powerful Graphic Processor Unit (GPU) Module

- Instant Bonding Compressible Pressure Sensitive Adhesive Tape and Pad

- Compressible Phase-Change Interface Pad Proven for Performance

| GPU and Other Module Mounting Thermal Adhesives | |||

| PROPERTY/PARAMETER | RTC8550 | RTK 7559-LB | ME 7159-LB |

| Dielectric Strength (Volts/mil) | Not Applicable | >750 | >750 |

| Device Push-off Strength (psi) | >1000 | >1000 | >1000 |

| Cured Density (gm/cc) | 4.5 | 2.5 | 2.5 |

| Thermal Conductivity | > 8.0 W/m-°C | > 8.0 W/m-°C | > 12 W/m-°C |

| Maximum Continuous Operation Temp. (°C) | > 150 | > 150 | > 150 |

| Electrical Resistivity | <3×10-⁴ ohm-cm | >10¹⁴ ohm-cm | >10¹⁴ ohm-cm |

What distinguishes AIT CPU, GPU and memory modules electronic adhesive and thermal management material solutions besides the unparalleled and proven low thermal resistance is it proven long-term reliability. In the die-attach, module mounting and heat-sink thermal interfaces, its patented compressible phase-change interface pads and the long-term reliability and consistent performance after years of thermal shock and cycling with the build-in stress relief with molecular flexible structures are the corner stones of the company products since its founding.

|

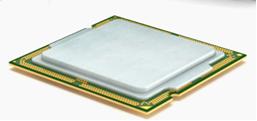

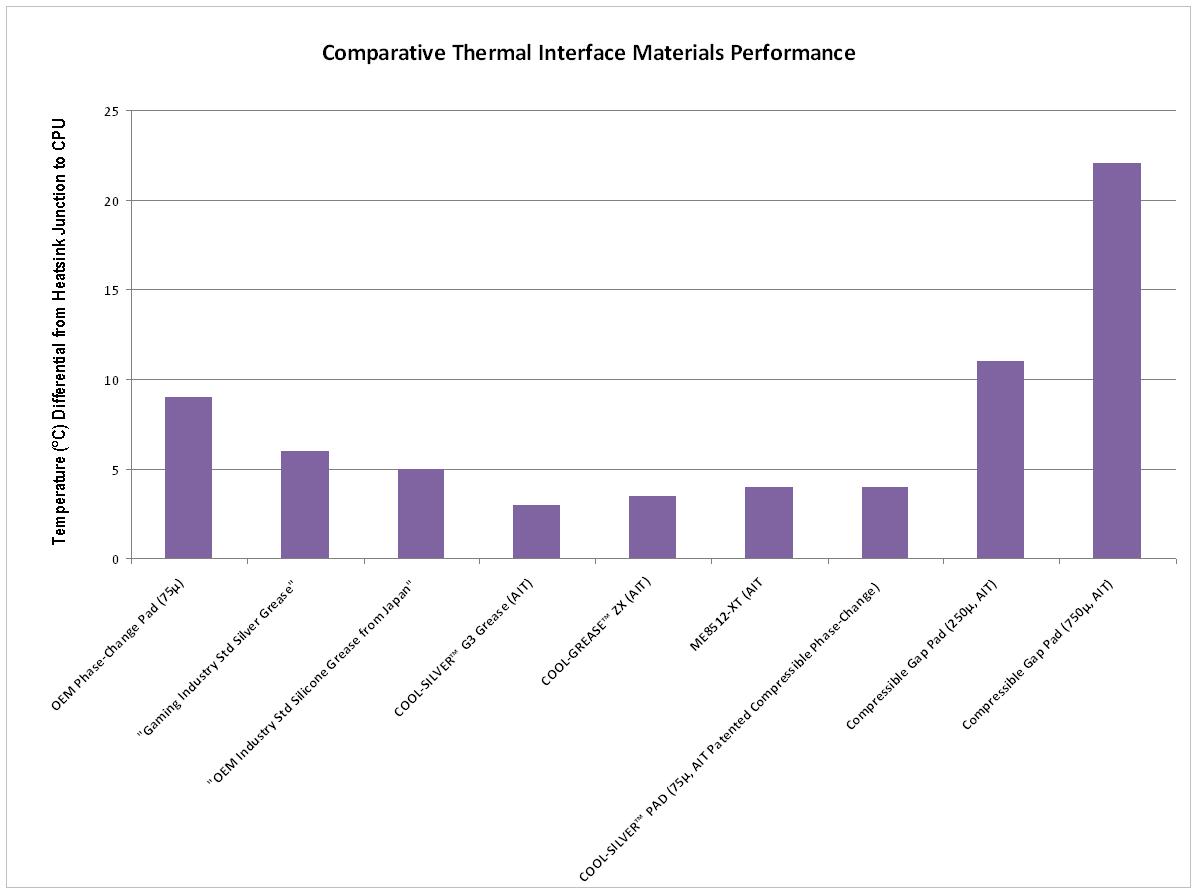

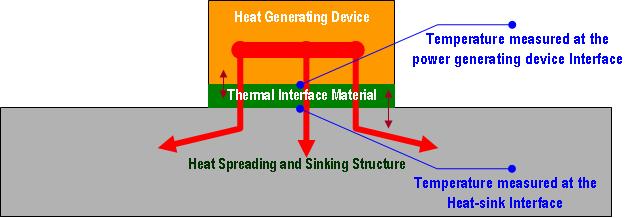

Comparison of Thermal Interface Materials Performance: Lower temperature rise represents a measurement of the efficiency of the thermal interface materials in transferring heat generated by the power electronic device to the heatsink (with fan) that dissipates heat to the environment by the forced circulating air. The thickness of the thermal interface material also contributes significantly to the efficiency of heat dissipation and should be minimized as much as the physcial configuration or construction permits. The effectiveness of a specific thermal interface material cannot be easily predicted by the claimed or even measured bulk thermal conductivity data or value: the thermal resistance at the thermal interface material to the substrates in their respective interfaces for thin bondline or interface thickness are significant and represents the “coupling efficiency” that cannot be predicted and must be measured.

The data in the comparison of thermal interface materials are collected by using an Intel CPU and forced air heatsink as represented in the above configuration. A thermocouple is drilled and embedded at the heatsink junction that interface with the thermal interface material to provide direct temperature data at the interface for measuring the “coupling” of the specific thermal interface materials to the heatsink.

For more information and recommendation assistance in managing die-attach reliability and module thermal interface management, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308