Protective Conformal Coatings for Metals and Coated Metals Against Marine Seacoast Environment of Salt Fog, Salt Spray Exposure and Direct Salt Water Immersion with Outstanding UV Resistance

Properties of AIT Marine Seacoast and UV Protection Coatings (Paints)

|

New Generation of Protection Coating-Paint Around Marine Seacoast Corrosion and Against Salt Fog, Salt Spray and Salt Water Immersion

According to the Marine Corrosion Forum, year upon year the cost of marine corrosion has increased until it is estimated today at 4 % of the Gross National Product. An enlightened approach to materials selection, protection and corrosion control is needed to reduce this burden of wasted materials, wasted energy and wasted money. Understand the causes of marine corrosion and the way in which protective coatings and systems along with more resistant materials can reduce or entirely eliminate sea water corrosion problems.

Many different types of destructive attack, “aqueous corrosion” can occur to structures, ships and other equipment used in or near sea water service with atmospheric corrosion of metals exposed on or near coastlines, and hot salt corrosion in engines operating at sea or taking in salt-laden air (salt fog) also require a systematic approach and protection coatings to eliminate or manage them.

How can marine corrosion be controlled? Key factors in prevention of marine corrosion are design, selection of materials, construction, use and maintenance. Among the main methods for controlling the tendency of metals to corrode in sea water, painting or coating helps to isolate the corroding metal from sea water or salt fog is one of most effective methods that can be applied with and after or without and as post installation after thought protection.

According to the Marine Corrosion Forum, corrosion was found to be responsible for 30% of failures on ships and other marine equipment. These are expensive errors arising from the selection and use of unsuitable materials and are compounded by ever increasing penalties on vessels, civil and military for breakdown and unnecessarily short intervals between outages for major repairs. On offshore platforms the cost penalty for replacement of failed equipment is several times that required for a similar onshore facility, and this does not take into account any losses of oil or gas production.

AIT marine protection coatings are engineered to be applied as primary or maintenance protection coatings that can be applied onto existing coating or paint to provide additional salt water or salt fog protection. They can be typically applied without preparation other than normal reasonable cleaning. CC7090-M is specially designed with additional function of protection against microbiologic or microbial attack for both direct immersion and salt laden environments. SC7050 and SC7130 are transparent PVDF based decorative coating for protecting metal surfaces against salt fog and UV exposures.

Comparative Protective Coating Performance for Moisture and Sea Water

| AIT Specialty Flexible Hydrophobic Coatings | Acrylics & Polyurethane Based Coatings | Silicone Based Coatings | Traditional Rubber Based Coatings | Epoxy Based Coatings |

|---|---|---|---|---|

| Moderate bond strength to most substrates | Moderate bond strength to variety of substrates | Moderate bond strength to most substrates | Moderate bond strength to most substrates | Excellent bond strength to most substrates |

| Flexible | Semi-flexible | Soft and flexible | Flexible | Flexible |

| Up to 125°C continuous & higher intermittent | Up to 125°C with decreasing bond strength with increasing temp | Up to 300°C continuous & higher intermittent | Up to 125°C with decreasing bond strength with increasing temp | 150°C continuous, 300°C intermittent |

| Good flexibility to -55°C | Fair flexibility to -20°C for most | Good flexibility to -55°C or better | Good flexibility to -45°C for most | Mostly not flexible |

| Engineered and proven outstanding moisture and salt fog, water and salt water immersion protection for aluminum, copper, steel and almost all coated metals | Fair to poor water, moisture and salt fog protection | Good water resistance and fair for salt fog protection | Fair to poor water, moisture and salt fog protection | Fair to water, moisture and salt fog protection |

| Outstanding UV resistance for most formulations | Moderate UV resistance and may be enhanced with UV blockers | Excellent UV resistance | Fair UV resistance and may be enhanced with UV blockers | Moderate UV resistance and may be enhanced with UV blockers |

| Engineered for outstanding tolerance to low temperature | Most have poor tolerance to low temperature | Excellent aging | Excellent aging | Excellent aging |

| Removable with suitable solvents | Tough to remove and with residuals | Removable with some residuals | Removable with some residuals | Removable with some residuals |

| Fair chemical resistance | Good chemical resistance | Good chemical resistance | Fair chemical resistance | Excellent chemical resistance |

| Fair to most solvents; poor resistance to petroleum solvents for CC-7090 series | Fair solvent resistance | Fair solvent resistance | Fair solvent resistance | Good solvent resistance |

| Salt water and salt fog protection; UV protection | General purpose applications | Specialty for high & low temp applications | General purpose applications | Specialty applications |

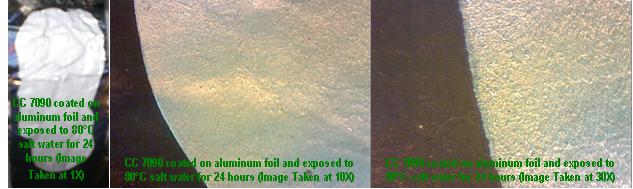

The above pictures are taken with moisture barrier coating on aluminum foil that are easily corroded by salt-water and salt fog. A 5 micron coating of CC7090 provides adequate protection to the aluminum surface while the parts that are not protected showed dramatic tarnishes (dark-brown “colored”). CC7090 is available as unfilled or filled with UV blockers materials. They are particularly useful for electrical devices, contacts, joints and printed circuit boards that may need additional conformal protection with extended long-term exposures. CC7090 represents a specialty formulated coating that focus in water and salt water immersion, salt fog and high moisture protections for metals and intermetallic joints against corrosion. The same effective protection have also be tested and proven for copper, steel and almost all coated metals.

CC7133 series of coatings available in different colors are designed to provide extreme protections against moisture, salt fog, salt water exposed coated metals when applied directly. They are also ideal in providing additional life and dramatically lower the maintenance costs for large infrastructures such as bridges, light houses and other structures along the sea coasts.

For more information and recommendation assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308