AUTOMOTIVE ELECTRONIC ADHESIVES & THERMAL INTERFACE MATERIALS FOR POWER ELECTRONICS

Unique Challenges for Automotive Electronic Adhesives & Thermal Interface Materials:

While the functional aspects of the typical die-attach, component attach, substrate attach and thermal management are the same for all of the automotive electronics, automotive electronics operational temperature tends to be a lot higher and conditions a lot harsher.

The temperatures of power electronics like insulated gate bipolar transistors (IGBTs) can operate around 150C. Some electronics may be exposed to solvents (fuels) and other chemicals.

With over 30 years of experience in inventing and formulating specialty adhesives for electronic applications, AIT provides one of the most comprehensive thermal interface solutions that are engineered to facilitate manufacturability and throughput:

- High thermal automotive power electronic die-attach pastes

- Compressible pressure sensitive thermal tape and thermal film adhesives that have been proven industry best to provide instant bonding and lowest thermal resistance for large area module mounting

- Conformal compressible phase change or pressure sensitive thermal interfaces for modules to heat-sink thermal interface for largest displays

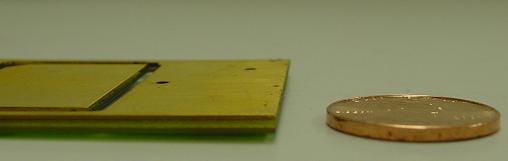

- Camber-free insulated metal thermal substrate for metal-core printed wiring board (MCPWB) with measurable 2x better thermal conductivity

Electro-Thermal & Dielectric-Thermal Die-Attach

- Low Thermal Resistance for Higher Power Automotive Electronics

- Modified Epoxy for camber-free Bonding

- Maintain Stable Bond Strength for Extreme Thermal Shock and Cycling

| PROPERTY/PARAMETER | ME 8512 | ME 8456-DA | MC8880 | ME 7519-LB |

| Electrical Resistivity | <0.0003 ohm-cm | <0.0003 ohm-cm | <0.003 ohm-cm | >10¹⁴ ohm-cm |

| Viscosity @5.0 rpm/Thixotropic Index | 10,000 cps/4.0 | 20,000 cps/4.0 | 10,000 cps/4.0 | 20,000cps/>3 |

| Glass Transition Tg (°C) | 52 | -20 | 220 | 52 |

| Device Push-off Strength (psi) | >3000 | >2000 | >3000 | >3000 |

| Hardness (Type) | ~ 80D | ~ 80A | ~ 99D | ~ 85D |

| Cured Density of Conductive Adhesive Portion (gm/cc) | 4.0 | 4.8 | 4.0 | 2.5 |

| Thermal Conductivity | > 12.0 W/m-°K | > 12 W/m-°K | > 8 W/m-°K | > 12 W/m-°K |

| Linear Tab-Composite Thermal Expansion Coefficient (ppm/°C) | 40 (X-Y=Z, Isotropic) | 90 (X-Y=Z, Isotropic) | 26 (X-Y=Z, Isotropic) | 45 (X-Y=Z, Isotropic) |

| Maximum Continuous Operation Temperature (°C) | > 180 | > 180 | > 250 | > 180 |

| Decomposition Temperature @5% weight loss (°C) | >450 | >450 | >500 | >450 |

| Recommended Curing Temperature/Time (°C/min.) | >175/10 | >175/10 | >150/10 | >175/10 |

Lowest Possible Die-Attach Thermal Interface is teh Foundation of Automotive Power Electronics Thermal Management:

Die-Attach thermal management is the first and most critical layer of the thermal stacks in a power electronic and LED module devices. Highest thermal conductivity with thin and void-free bond-line of the die-attach adhesive is critical in dissipating the heat quickly to the broader sub-mount and eventually to the heat-sink.

| Module Mounting and Sub-Mounting Thermal Adhesives | |||

| PROPERTY/PARAMETER | RTK 7555 | RTK 7554 | ME 7519-LB |

| Thermal Conductivity | > 0.2 W/m-°C | > 0.2 W/m-°C | > 0.2 W/m-°C |

| Dielectric Strength (Volts/mil) | >550 | >300 | >750 |

| Device Push-off Strength (psi) | >1000 | >1000 | >1000 |

| Cured Density (gm/cc) | 2.5 | 2.5 | 2.5 |

| Thermal Conductivity | > 3.0 W/m-°C | > 8.0 W/m-°C | > 12 W/m-°C |

| Maximum Continuous Operation Temp. (°C) | > 150 | > 150 | > 150 |

| Electrical Resistivity | >10¹⁴ ohm-cm | >10¹⁴ ohm-cm | >10¹⁴ ohm-cm |

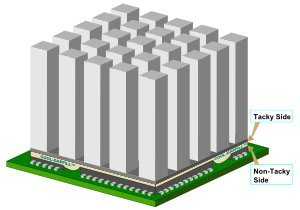

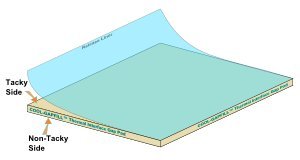

Extreme Thermal Adhesive for Module Mounting

- Instant Bonding Compressible Pressure Sensitive Adhesive Pad

- Melt-tacking and In-situ Curable Low Thermal Resistance Film Adhesive

- Proven Lower Junction and Device Temperature

Compressible Phase-Change Thermal Interface Pads

- Compressible and conformal couples with phase change to allow elimination of voids

- Proven for most stringent applications including military applications

- US patented innovation

- Non-silicone and non-contaminating

| Other AIT Thermal Interface Materials for Automotive Power Electronics Applications | ||

| FUNCTION | AIT PART # | THERMAL, ELECTRICAL AND OTHER RELEVANT PROPERTIES |

| Compressible Phase-Change | COOL-SILVER™ PAD CPR8850-LB |

|

| Compressible Phase-Change | COOL-SILVER™ G3 PAD |

|

| Compressible Phase-Change | COOL-PAD™ CPR7158 |

|

| Compressible Phase-Change | COOL-PAD™ CPR7155-LB |

|

| Gap-Filling Thermal Pad | COOL-GAPFILL™ DT, TT |

|

| Compressible Gel-Film | COOL-GELFILM™ SZ |

|

| Thermal Grease | COOL-SILVER™ G3 Grease |

|

| Thermal Grease | COOL-GREASE™ CGR7559-LB |

|

| Thermal Gel | COOL-SILVER™ G3 Gel |

|

| Electro-Grease | COOL-GREASE™ CGR8550 |

|

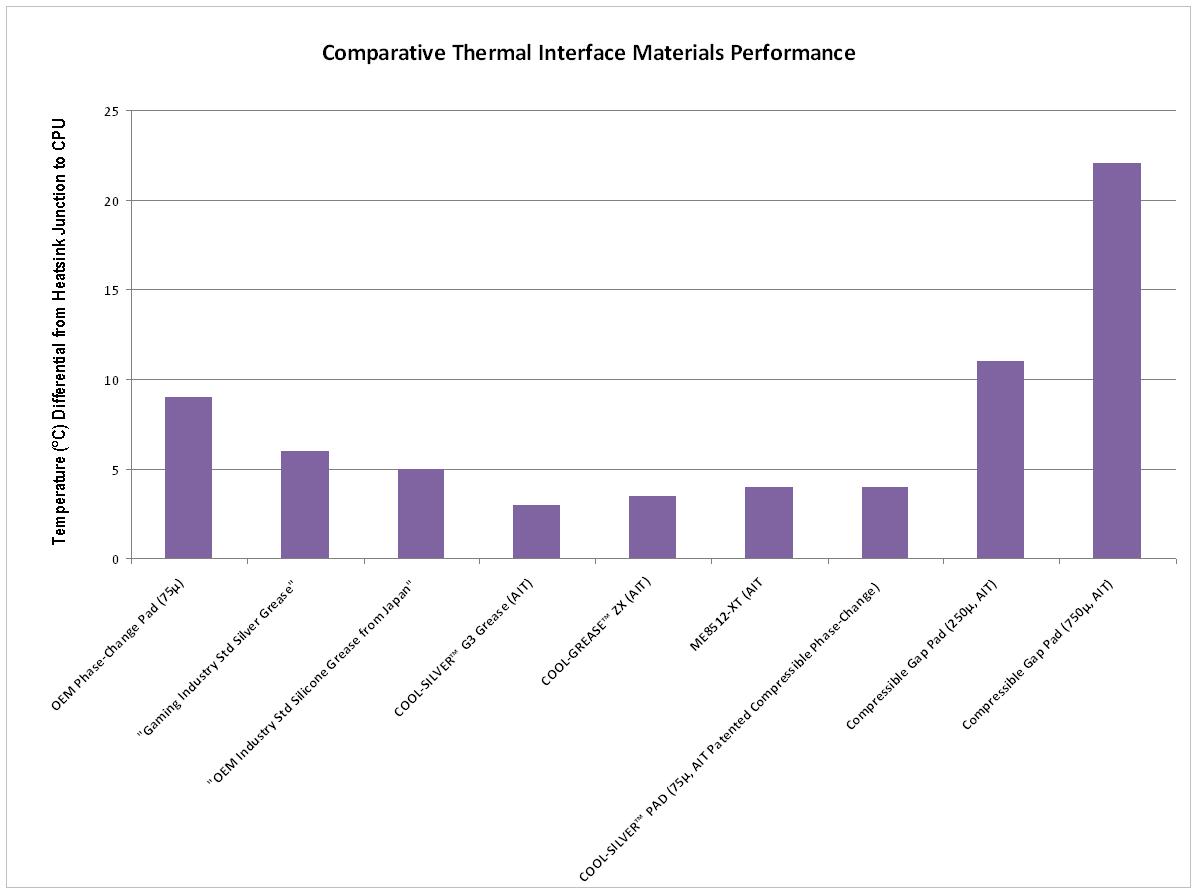

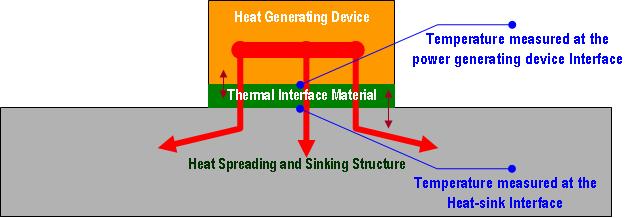

Comparison of Thermal Interface Materials Performance: Lower temperature rise represents a measurement of the efficiency of the thermal interface materials in transferring heat generated by the power electronic device to the heatsink (with fan) that dissipates heat to the environment by the forced circulating air. The thickness of the thermal interface material also contributes significantly to the efficiency of heat dissipation and should be minimized as much as the physcial configuration or construction permits. The effectiveness of a specific thermal interface material cannot be easily predicted by the claimed or even measured bulk thermal conductivity data or value: the thermal resistance at the thermal interface material to the substrates in their respective interfaces for thin bondline or interface thickness are significant and represents the “coupling efficiency” that cannot be predicted and must be measured.

The data in the comparison of thermal interface materials are collected by using an Intel CPU and forced air heatsink as represented in the above configuration. A thermocouple is drilled and embedded at the heatsink junction that interface with the thermal interface material to provide direct temperature data at the interface for measuring the “coupling” of the specific thermal interface materials to the heatsink.

AIT application engineering, sales, chemists, and material scientists are ready to serve your special needs and applications. Please inform us of your requirements using the Contact tab or click on the button below:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308