Near Hermetic Cavity Electronic Packaging Solutions Beyond B-Staged Epoxy Lid-Sealing

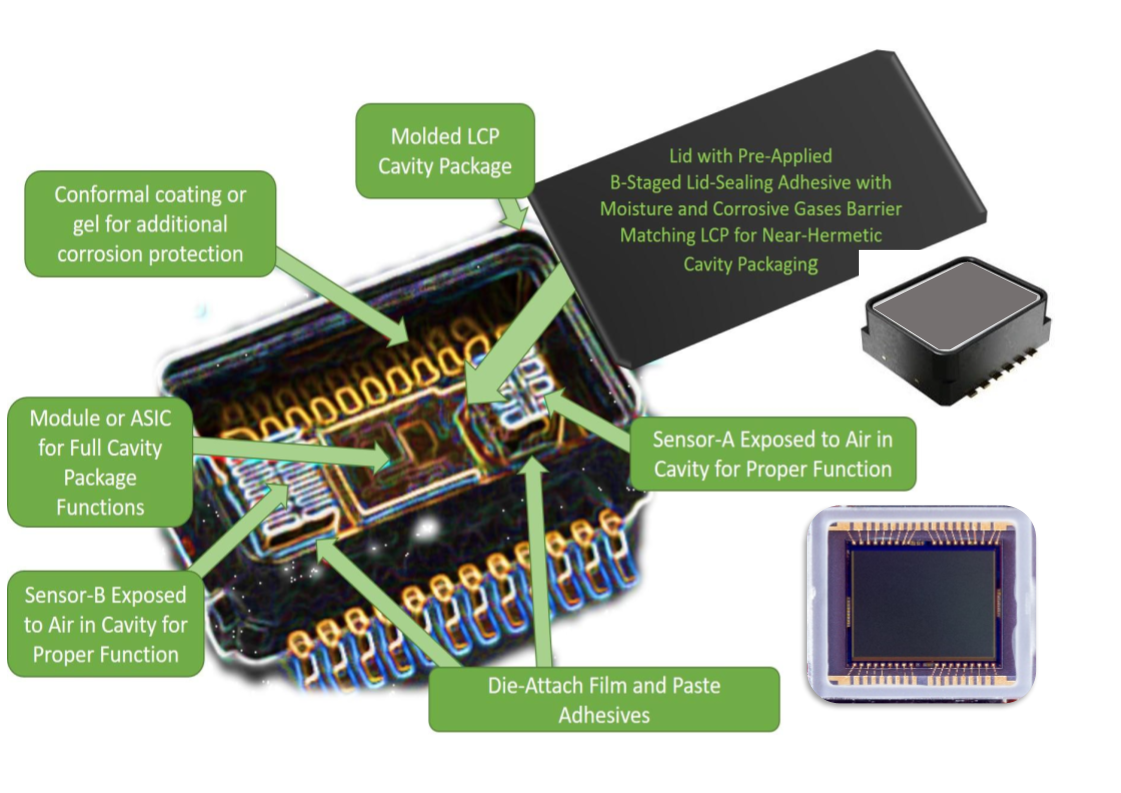

If we closely examine the protection required for cavity packaging with single and multiple chips, there are other complementary sealing solutions meeting the protection against moisture-ionic-corrosive gases combination with sealing coating and sealant that have LCP level of the barrier. For example, instead of relying on the lid-seal bonding for the barrier, if the geometry configuration allowed or if deemed more convenient for inline manufacturing process rather than batch processing:

- The lid-sealing can be done with instant melt-bonding B-staged or pre-applied adhesive that may not have the only temporary capability for the final lid-sealing requirements.

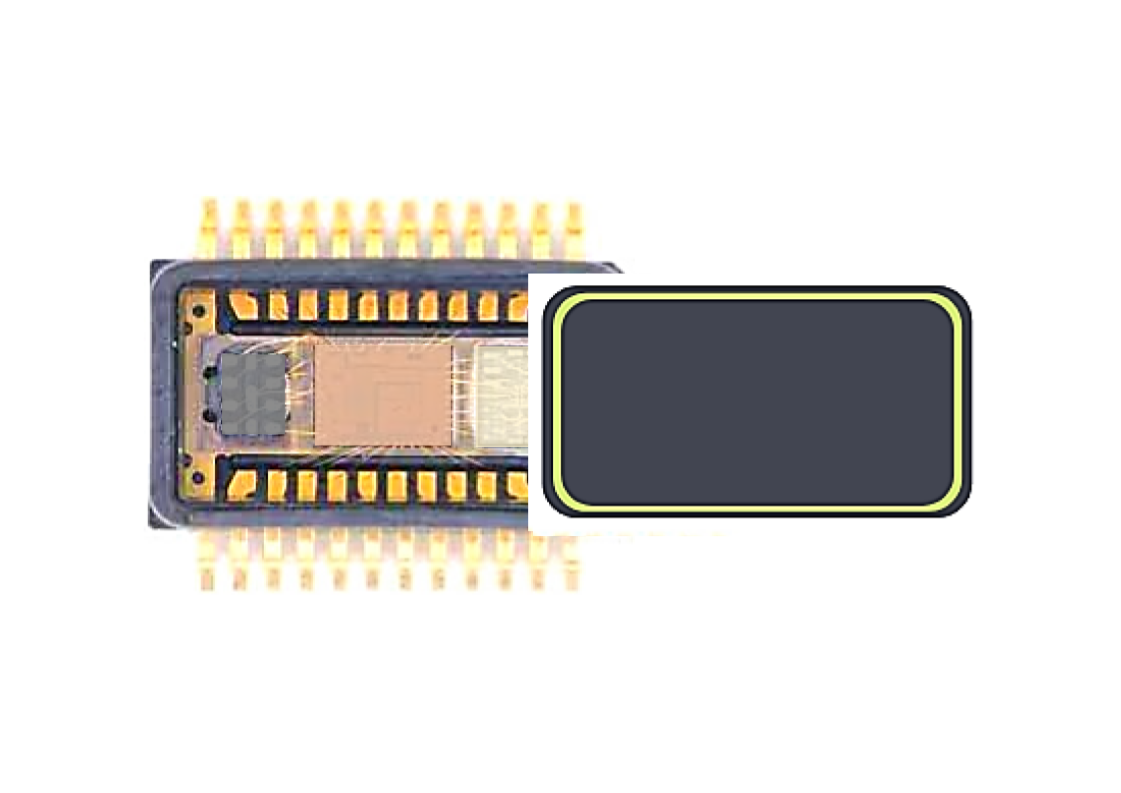

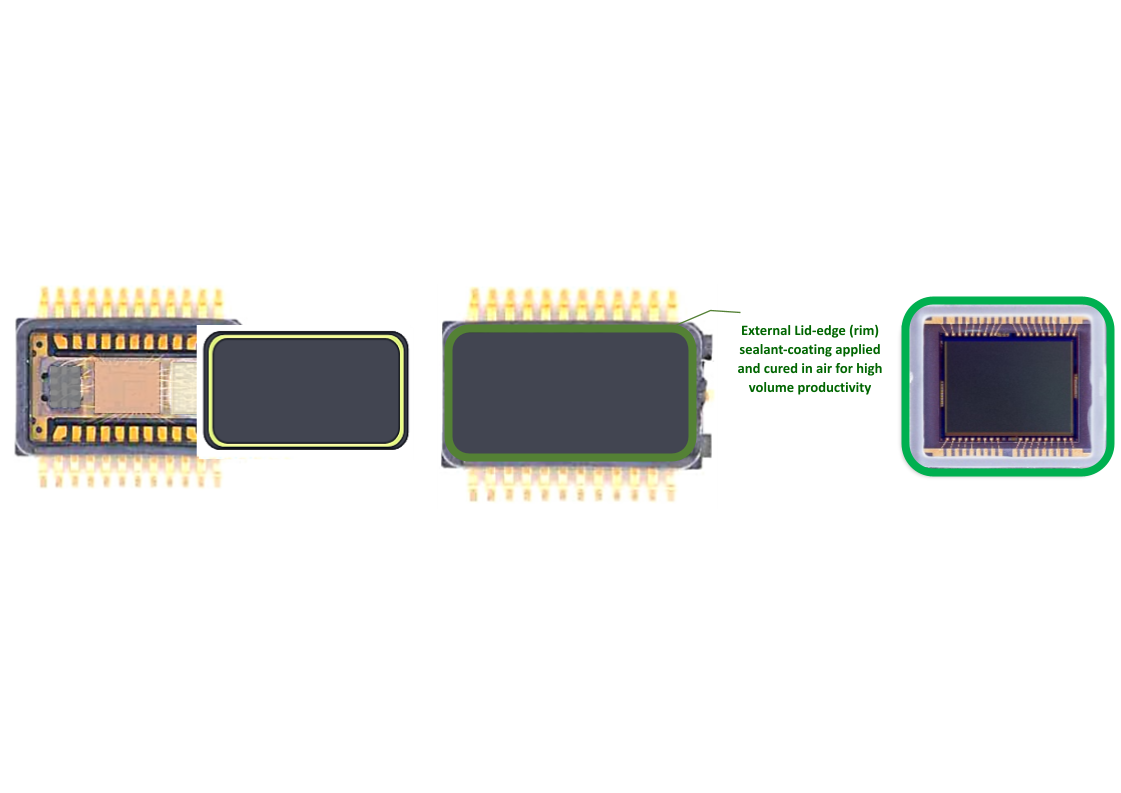

- One possible process is to instantly pick-and-place and melt-bond lid with pre-applied TP7130 (from AIT) at 150°C under an inert environment. Subsequently, high-temperature capable lid-seal can be applied onto the lid rim edge to provide additional mechanical strength such as LS-LCXP7450 which has FLUOROSEAL® level of moisture and corrosive gases barrier. This lid-sealing paste can be dispensed and cured without applying any additional pressure or inert gas provision.

- Another possible process is for use in device lid-sealing that may be difficult to use traditional lid-sealing processes of controlled uniform pressure and temperature for an extended time such as extra-large modules or transparent imaging devices. In this case, the rapid curing lid-seal adhesive or rapid UV curing adhesive for partial curing at higher temperature with UV for balancing cavity pressure. Rim-edge sealants such as FLUOROSEAL® LS-CXP7450 or LS-SC7150 may be subsequently used to provide the ultimate moisture and the corrosive gases barrier layer.

For more flexibility in designing a high-volume in-line lid-sealing process, AIT has another unique and innovative lid-sealing FLUOROSEAL that combine the B-staging, instant melt-bonding, and subsequent UV post-curing without pressure:

- World-first UV curing lid-seal FLUOROSEAL® LS-UVF7350 adhesive film adhesive that can instant melt-bonded to form lid-sealing in high volume inline production with post-curing in the air if necessary.

- Another possible high volume production process is to use the instant melt-bonding LS-TP7150 on cap-wafer or B-staged LS-LTP7150 on lids that form and seal the devices at 150°C with nominal placement pressure of less than 10 psi. To provide solderability high-temperature mechanical stability, the lid-edges mechanical sealing adhesive may be applied subsequently and cured at a suitable temperature in the air.

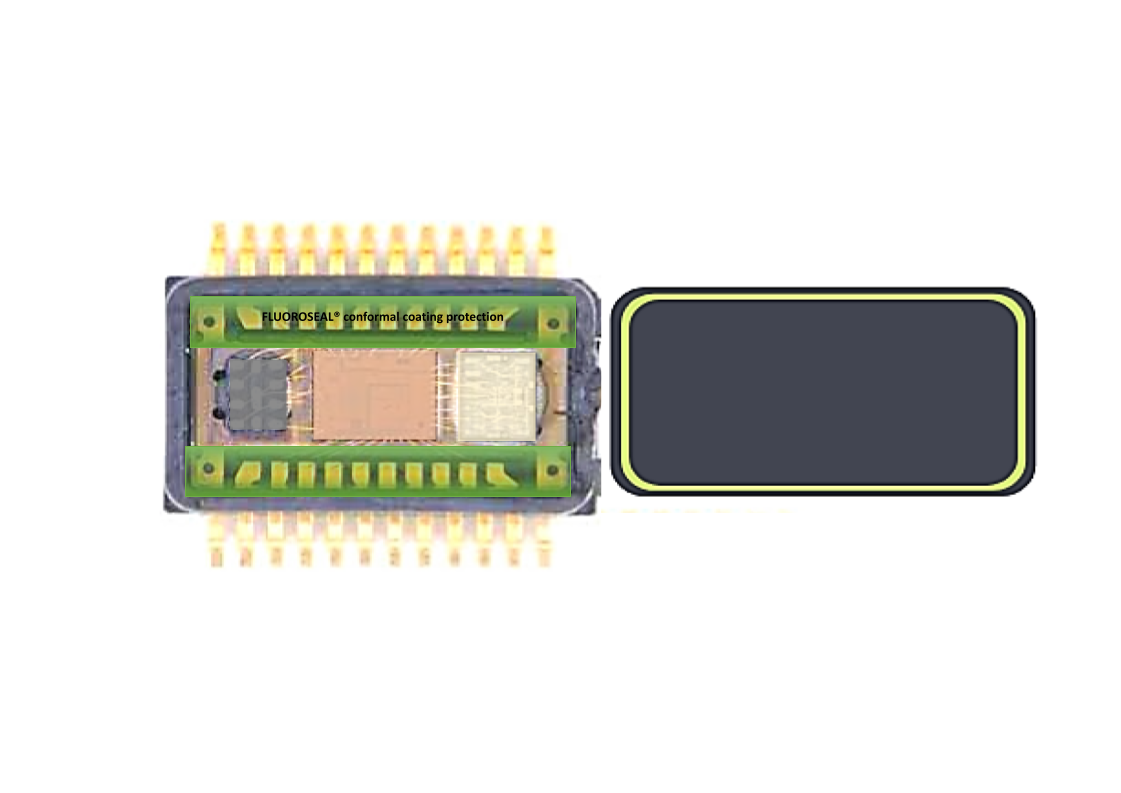

In some integrated cavity packaging with multiple devices, near hermetic lid-sealing requirements may be lowered and still maintained the long-term reliability such as properly protected high-performance circuit boards

- With proven FLUOROSEAL® conformal coating SC7130-CC may be used on top of conductive traces and contact pads to provide moisture and corrosive gases barrier.

- Higher performance lid-sealing sealant-coating may be added on the lid-rim and edges if deemed necessary. This post-lid-seal coating sealant can be performed in the air for high volume productivity.

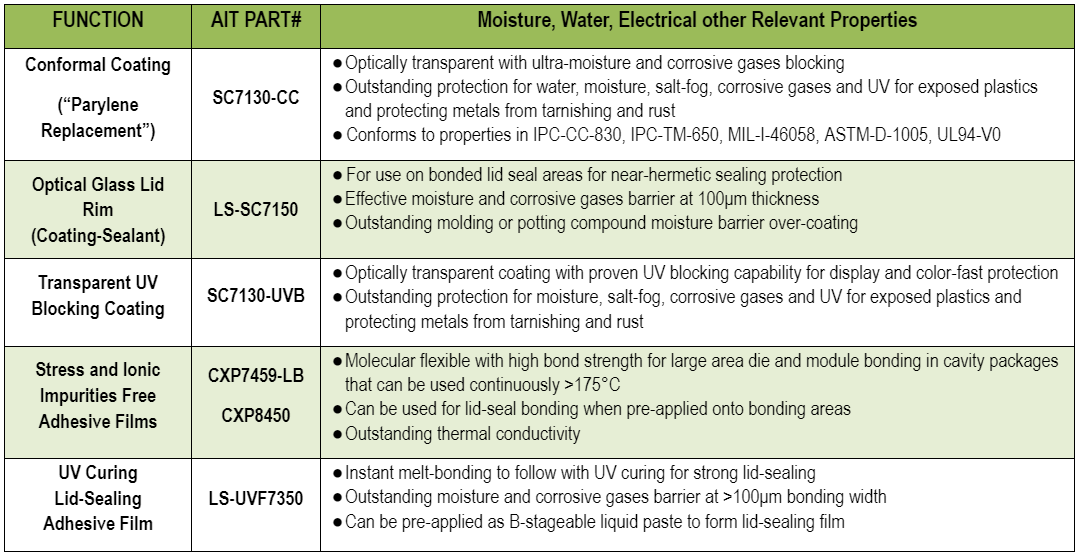

The following are some examples of the FLUOROSEAL® moisture and corrosive gases barrier protection: