Order Sample

Order some of our Conformal Coating samples

Conformal Coatings for Unparalleled Electronic Printed Circuit Board Protection:

- Ultra-Hydrophobic (Repels Water Completely)

- Super Non-Hygroscopic (Does Not Absorb or Retain Moisture)

- Moisture Blocking

AIT Conformal Coatings are proven in protecting Automotive Electronics, Aerospace and Military Electronics, Marine and Shipboard Electronics, Solar Power Electronics, Medical Electronics, Mobile Consumer Electronics, and Outdoor Electronics

FLUOROSEAL™ SC7130-CC conformal coating is a new class of fluorinated polymer conformal coating that provides one of the only sulfide protection for soldering contacts and against corrosive gases.

CIRCUITSEAL™ CC7130-PRTC conformal coating is proven to protect circuits functioning when submerged in water and salt-water intermittent

Read our white paper:

Designing Polymer Molecular Structure for Conformal Coating for Optimized Printed Circuit Board Protection Against Outdoor and Extreme Elements

FLUOROSEAL SC7130-CC and CIRCUITSEAL CC7130-PRTC

Novel Protective Conformal Coatings

from AI Technology, Inc.

for Outdoor Environments and Extreme Weather

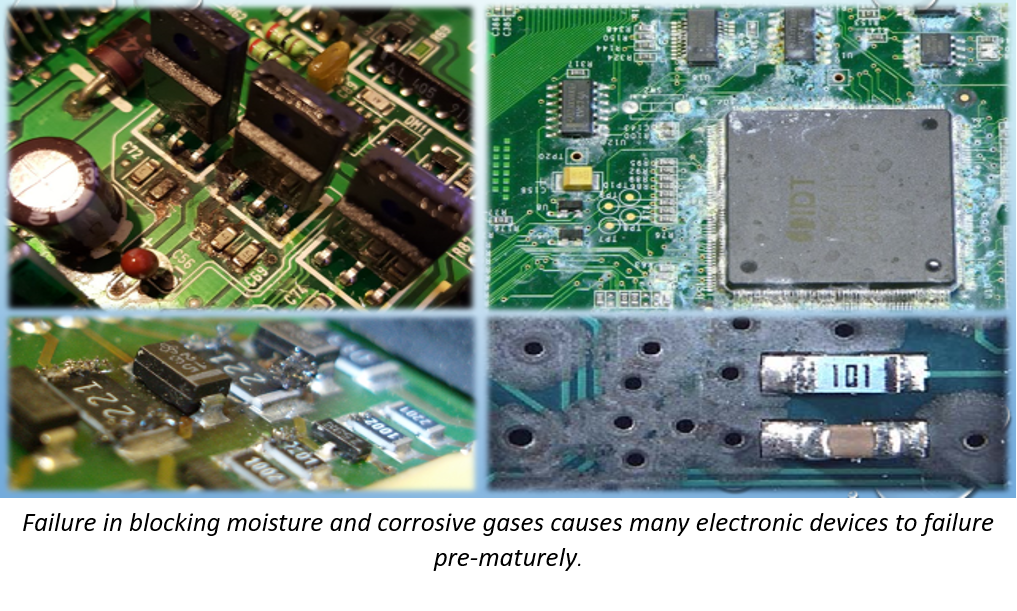

With the advance of microelectronics in everyday life, a growing number of sensors, processors, and communications equipment operate in severe environments. Aeronautic, maritime, and industrial electronics face harsh operating conditions and a large and increasing amount of commercial electronics such as LED displays and automotive electronics are used outdoors. Advanced protective coatings that can be applied cost effectively are needed for the long-term life and reliability of these microelectronics.

AI Technology introduces two new types of conformal coatings that are qualified under the IPC-CC-830C standards of testing and meet the Mil-Std requirements of MIL-I-46058.

The key difference in these new types of conformal coatings is the

ability to block moisture and corrosive gases

while being hydrophobic for

unparalleled conformal circuit protection.

Both types of conformal coatings can be applied with

standard spray-dip-brush methods and air dry at ambient temperature

for thickness of 15-50 microns and

“Parylene-type” performance.

Today’s advanced outdoor electronics may be exposed to high humidity, salt-fog and salt-spray, temperature variance or even thermal shock, and industrial atmosphere laden with corrosive gases like sulfur dioxide, hydrogen sulfide, nitrogen dioxide, etc. Millimeter frequency devices, like those used with 5G, feature fine-pitch components and leads separated by smaller, ever closing distance, creating a greater need for prevention of ionic migration.

See IPC-CC-830C standards test report summaries for

FLUOROSEAL SC7130-CC and CIRCUITSEAL CC7130-PRTC

For Industrial & Structural Coating Applications, please visit www.aitcoatings.com

Watch our video about AIT conformal coatings!

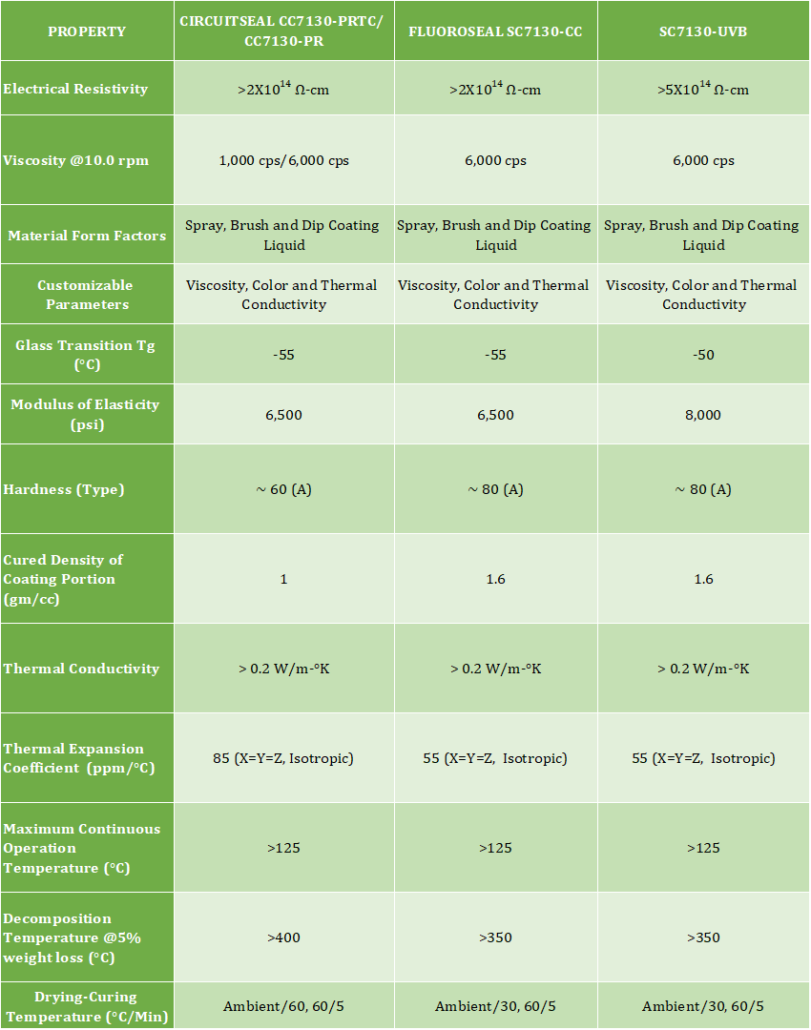

See more physical and electrical properties of FLUOROSEAL SC7130-CC and CIRCUITSEAL CC7130-PRTC