New Generation of Ultra High Tg Underfill

with Glass Transition of Over 240°C for Ultimate Flip-Chip and Component Stress Management

Besides the underfills for stress relief of BGA packages for solder-reflow interconnections, with more semiconductor design and packaging utilizing fan-in and fan-out wafer level packaging (FO-WLP), underfill that can manage large area chip with copper pillar and gold bumps down to less than 35μm and advancing toward 25μm required different underfilling technology and solution.

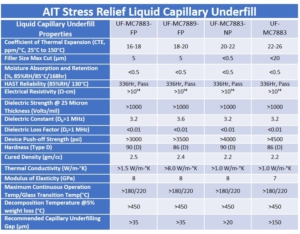

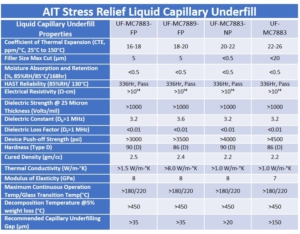

AI Technology, Inc. (AIT) have been utilizing its proprietary modified cyanate ester technology to provide both extra-high glass transition (Tg) and low viscosity for fast chip underfill successfully in the last few years. UF-MC7883-FP is a new generation of capillary underfill solution that have been proven to provide stress relief for chips with less than 35μm gap. With close to 80% fill with engineered micron sized silica, coefficient of thermal expansion (CTE) has been controlled to less 16 ppm/°C. The demonstrable low CTE and high Tg enable UF-MC7883-FP to provide slight compressive stress and low shear stress for WLP and package-on-package (PoP) and chiplets devices.

Wafer level and chiplets packaging required capillary underfill having much lower CTE and capillary gap-filling than those used in BGA board level packaging. UF-MC7883-FP introduced by AIT has been proven to meet the reliability performance of low CTE and stress absorption besides providing fast capillary filling productivity.

With AIT proprietary stress absorbing modified cyanate ester technology along with its controlled low CTE, even at high Tg of close to 220°C, the shear stress is controlled to minimal level to allow passing of the extreme thermal cycling requirements from -65°C to 150°C for the larger dies of 20mmx20mm. The inherent higher temperature stability of the cyanate ester molecular backbone, its has found some extreme applications at temperature beyond 175°C as well.

High Melt-Flow Film Underfill for FOW:

- Outstanding melt-flow and wetting to flow-over-wire for stack-chip applications

- Ability to cure at lower temperature from 100-150°C for lower interfacial stresses

- Ideal for large area stack-chip and module

- Preform with specific thickness accommodates the flip-chip or ball-grid-array parts with preformed cut-outs for interconnections allowing the film adhesive to flow and encapsulate for protection

Flow-Over-Wire underfill film adhesive is available in DDAF format for large scale wafer level packaging

Underfill Liquids and Film Adhesives:

| FUNCTION | AIT PART# | THERMAL, ELECTRICAL, & other RELEVANT PROPERTIES |

| Underfill Film Adhesive for Wafer or Chip | UFF-ESP7770 |

|

| Underfill Film Adhesive for Wafer or Chip (REWORKABLE) | UFF-RW-ESP7760 |

|

| Underfill Film Adhesive for Wafer or Chip | UFF-CXP7880 |

|

| Underfill Film Adhesive for Wafer or Chip (REWORKABLE) | UFF-RW-CXP7860 |

|

The ultra-high glass transition temperature (Tg) at 240°C minimizes tensile stress induced failures when the flip-chip packages are going through the reflow soldering of lead-free solder.

For more information and recommendation assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or fax: 609-799-9308