Solar Protective Coatings and Anti-Glare Energy Optimized Coatings for Solar Cells and Solar Panels, Decorative Metals and Coatings to Prevent Moisture-Water, Salt, UV or Combination Environmental Induced Degradation

Solar applications and civil structures that are exposed to direct sun light encounter some of the most challenging material complications. AIT has developed a specific series of protective coatings with different properties for the solar cell, module, panel and installation applications. All of these specialty coatings are made with proven fluorinated polymers engineered for outstanding adhesion on metals, glass and on most plastics used in solar and civil structural applications. AIT’s speciality coatings provide proven UV stability, moisture barrier protection and are embedded with specially designed electrical conductivity, high dielectric strength or anti-static properties for the intended application.

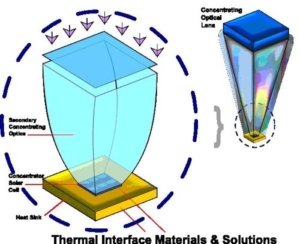

SOLAR-BLOC SC7115 is an electrically insulating and moisture resistant coating that has high thermal conductivity to help minimize heat hot-spot degradation while also protect against moisture induced long-term instability induced by galvanic, salt-fog, and moisture exposure.

These applications of UV resistant, high moisture barrier adhesive-coatings are specifically engineered to be compatible with the melt-bonding process to advance the speed of manufacturing that has been a hurdle in reducing the cost of solar applications. Previous pages discussed how AIT’s technologies can enhance tabbing and solar panel lamination. This page discusses how select application of AIT’s protective coatings and sealant-adhesives increase the long-term reliability of solar panels.

| AIT Solar Energy Optimization Enabling Coating, Sealant, Adhesive and thermal Interface Materials for SOLAR Applications | ||

|---|---|---|

| Function | AIT Part # | UV, Moisture, Thermal, Electrical & Other Properties |

| Anti-Glare Coating | SOLAR-THRU™ SC 7050-CLEAR |

|

| Insulating Coating & Moisture Barrier | SOLARBLOC™ SB 7155 |

|

| Anti-static Coating & Moisture Barrier | SOLARBLOC™ SB 9133 |

|

| Clear Decorative Solar Protective Coating | SC7050-PC |

|

| Colored Decorative Solar Blocking Protective Coatings | 1. SC7053-WHITE 2. SC7053-BLACK 3. SC7053-RED 4. SC7053-BLUE |

|

Physical structures made with metal, plastics and paints can be protected against moisture and salt fog induced corrosion and degradation with a thin coating of CC7133 with grey color or SC7090-UVB when transparency is required.

| Other AIT Adhesives & Thermal Interface Materials for SOLAR Applications | ||

|---|---|---|

| Insulating Thermal Interface | COOL-PAD™ CPR7153 |

|

| Conductive Thermal Interface | COOL-SILVER™ PAD CPR8850 |

|

| Electrical Interface Grease | COOL-GREASE® CGR8550 |

|

| Thermal Interface Grease | COOL-GREASE® CGR7093 |

|

For a recommendation, information or assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308