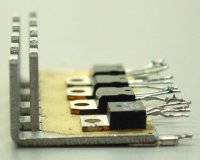

Flexible Film Adhesive For Reliable Substrate And Component Attach

AIT has pioneered the use of flexible substrate-attach film adhesives since 1985. Its flag-ship products such as TC8750 and ESP8450-WL have found many successful applications over the last 20 years. Continuing this innovative heritage, the following “Substrate and Component Attach Film” adhesives represent products that are engineered for both manufacturability and reliability. AIT’s products provide the following features:

- Molecularly flexible for stress-free bonding for large area substrates and components

- All specialty film adhesives are available in dry tack-free or tacky pressure sensitive formats for large and low volume manufacturing

- Ability to withstand 250°C exposure such as wire-bonding

- Low moisture absorption for ultimate reliability

- “Instant melt-bondable” thermoplastic substrate-attach films Electrically Conductive Film Adhesives

The following tables outline featured AIT products:

Electrically Conductive Film Adhesives

| AIT Product | Characteristics | Electrical Resistivity (ohm-cm) | Thermal Conductivity (watt/m-°C) | Die-shear (psi) | Tg (°C) | Film Type |

|---|---|---|---|---|---|---|

| <4×10-4 | >6.0 | >1,500 | -45 | Tack free dry film Preforms 3-12 mils (thick) | |

| RTC8750 |

| <4×10-4 | >6.0 | >1,500 | -25 | Tacky film Preforms 3-12 mils (thick) |

| TC8750 |

| <4×10-4 | >8.0 | >1,500 | 0 | Tacky film Preforms 3-12 mils (thick) |

Electrically Non-conductive Film Adhesives

| AIT Product | Characteristics | Electrical Resistivity (ohm-cm) | Thermal Conductivity (watt/m-°C) | Die-shear (psi) | Tg (°C) | Film Type |

|---|---|---|---|---|---|---|

| TK7758 |

| >1×1014 | >3.6 | >1,500 | -20 | Tacky film Preforms 3-12 mils (thick) |

| ESP7455 |

| >1×1014 | >2.0 | >1,500 | -45 | Tack free dry film Preforms 3-12 mils (thick) |

| RTK7556 |

| >1×1014 | >3.0 | >1,500 | -45 | Tacky film Preforms 3-12 mils (thick) |

| TP7155 |

| >1×1 | >2.0 | >1,500 | -40 | Tack free dry film Preforms 3-12 mils (thick) |

For a recommendation, information or assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308