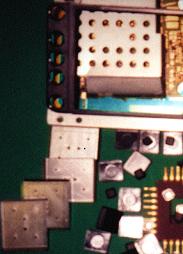

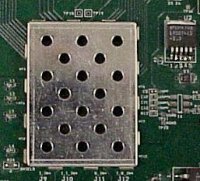

Pre-Applied Melt-Bonding & Pressure-Sensitive EMI/RFI Shielding Lid-Shield For UHF and Microwave Components and Boards

With the use of LEAD-FREE soldering, having to reach 250-300°C for the attachment and rework of shielding lids on components could potential damages sensitive components on the boards. AIT has designed a series of EMI/RFI shielding solutions incorporating direct attach EMI shielding, cans, covers, lids and caps. The following are some of the potential benefits of these patented products and applications:

- Allow inspection of finished products before attaching EMI/RFI cans and covers.

- Attachment either by mechanical insertion or instant melt-flow at 150°C.

- Flexibility of fully automated assembly or manual assembly.

- Optional complete shield without ventilation holes with compressible phase change thermal enhancement.

- Cost effective.

EMI Shielding Caps & Lids Solution and Process

1. Send lid design to AIT sales-engineering staff

- AIT can work with your parts that are either dropped shipped to AIT for adding shielding adhesive

- AIT can also produce the cans, caps or lids based on drawing for full-service solution

2. Review and approve lid or cap and adhesive coating design

3. AIT manufactures or used customer parts and coat adhesive preforms based on requirement.

4. AIT delivers lids or caps with adhesives on and ready for insertion on circuit board.

5. Place or insert lids with adhesive preforms onto board.

6. Reflow adhesive to form EMI shields onto devices

- Induce and observe flow of adhesive to lid perimeters

- AIT preforms are self-sealing with high flow to allow easy observation of sealing of all sides

7. Test for shielding and other qualities

8. Rework if necessary

EMI Metal Caps and Lids

| AIT Product | Process & Characteristics | Minimum Lid Width (mils) | Bond Strength (psi) | Electrical Resistivity(ohm-cm) |

|---|---|---|---|---|

| CB 8250-E (Self-tacking, Insitu-curable) |

| 3 | >600 | 5×10-4 |

| CB 8130 (Instant Melt-Bonding @130°C) |

| 3 | >600 | 5×10-4 |

| CB 8133 (Instant Melt-Bonding @130°C) |

| 3 | >600 | 5×10-3 |

| EMI Covers, Lids & Caps |

| 3 | >600 | Copper |

For more information and recommendation assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308