TEMPORARY BONDING FILM AND SPIN COATING ADHESIVES FOR HIGH TEMPERATURE 3D-TSV WAFER PROCESSING

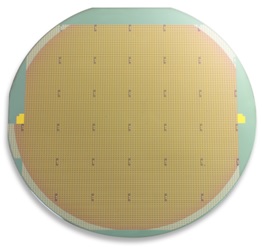

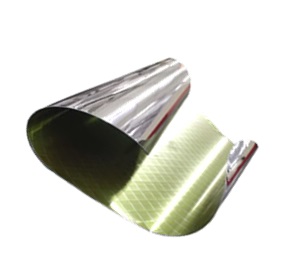

In wafer processing for TSV, in step 1, the device wafer is bonded onto the carrier wafer creating a compound wafer with a temporary bonding adhesive must be melt-bonded to conform and fill in and “planarize” to provide a void free bonding to accommodate and compatible with the features of the device wafer like surface topography, surface material, constraints in process temperature and pressure etc. Spin coating process is the established industry standard in putting on thin temporary bonding film onto carrier wafer. AIT wafer processing adhesive technologies besides offering the spin coating, is the first in the industry to provide a thin film adhesive application process that allow much higher flexibility and ease in customizing the required adhesive thickness from feature rich device wafer requiring 60 microns. With the available of film adhesive, the size of wafer that can be used is no longer limited to 200mm, 300 and even 450mm can be processed the same way.

In the Step 2 of the TSV process involves the thinning and subsequent backside processing of the device wafer to 60 micron or less. Depending on the particular application, many different processes are used to create the backside structure. Besides mechanical back grinding, processes like CMP, dry etching, CVD, lithography, PVD, wet etching and electro-plating with acid or base solutions are performed. AIT wafer processing adhesives are tested to be fully compatible with all these processes and bonding remains stable even under severe process of temperature higher than 320°C.

The next critical requirements of the wafer processing temporary bonding adhesive is in the step 3 of de-bonding or separation of the carrier wafer from the processed thin device wafer. Both the WPA-TS320 and WPA-TL330 adhesive solutions are engineered to allow traditional heat-sliding at relatively comfortable temperatures of 160-300°C and solvent assisted separation. The WPA-TL adhesive solution can also be separated with the more advanced laser assisted method. Residues, mostly in semi-film, from the temporary adhesive are removed with designed stripping solvent solutions.