True Near-Hermetic Cavity Electronic Packaging Lid-Seal Solutions

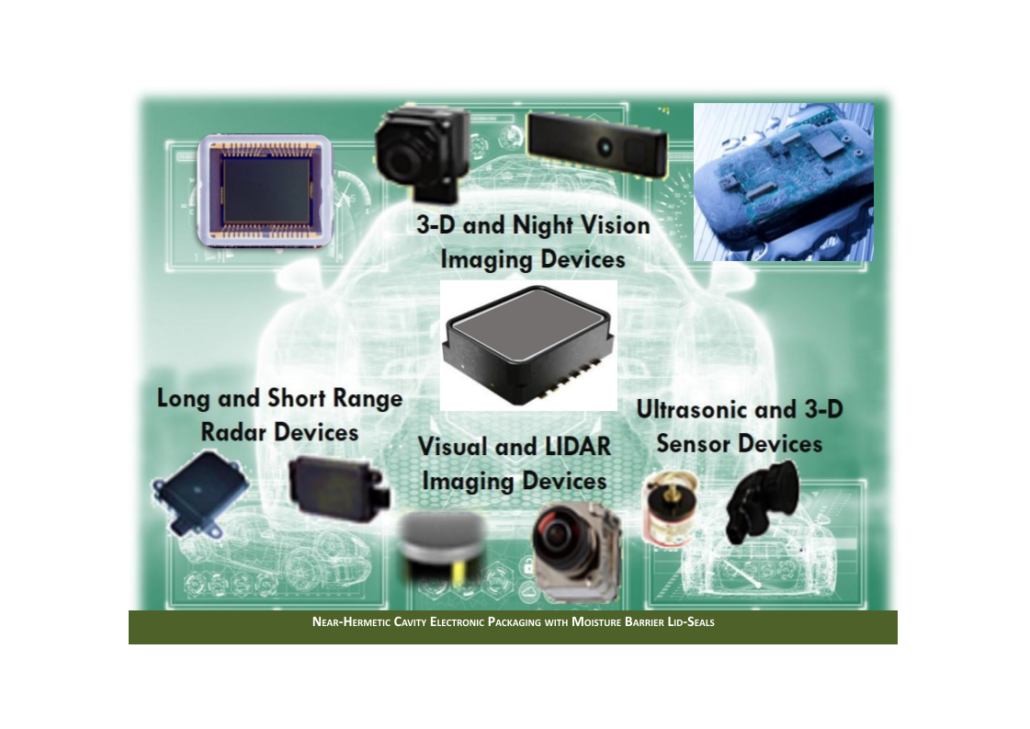

Cost-effective, near-hermetic cavity packaging of electronic devices is becoming more important for the commercial electronics used in electric vehicles, smartphones, and sensor devices driving automation of all kinds. The reliability of these imaging and sensor devices depends on the cavity keeping out of corrosive environments such as moisture in combinations with ionic impurities and corrosive gases.

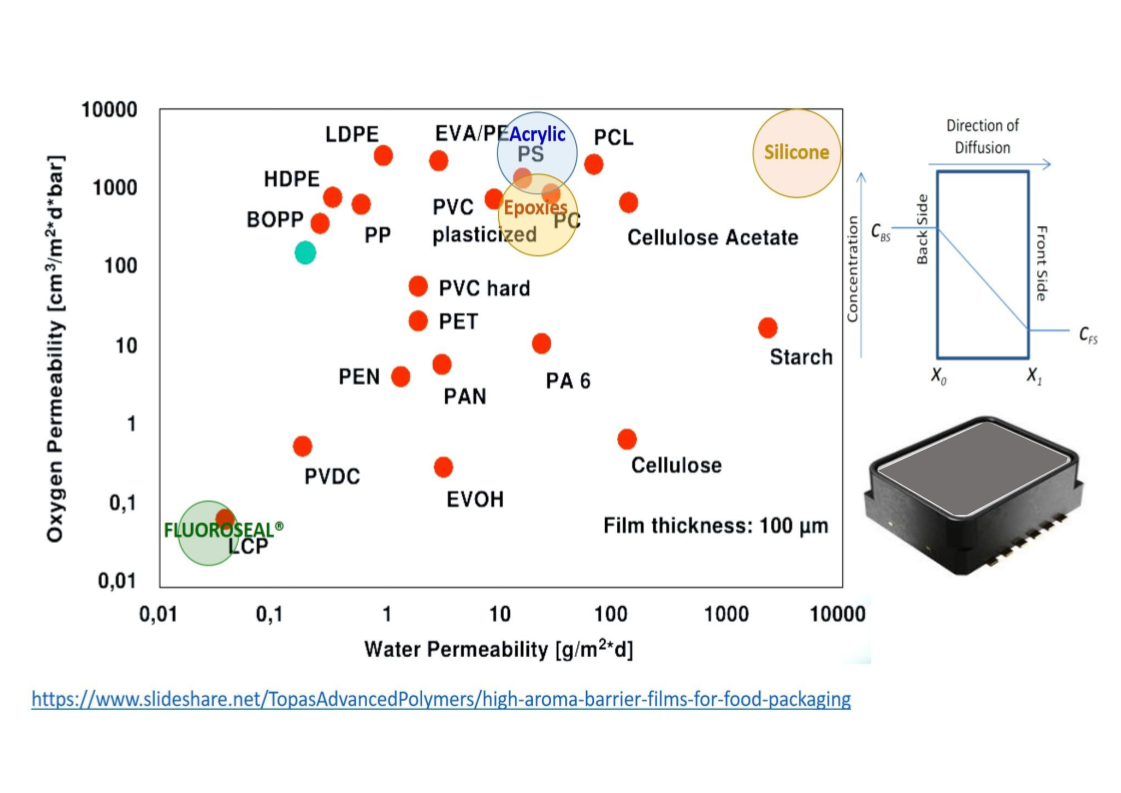

- Lid-Sealing adhesives and coating sealants must have the capability to keep out the moisture with a very small kinetic molecular diameter, similar to He. FLUOROSEAL® has now been proven to match that of LCP to block moisture and corrosive gases from penetrating the near-hermetic lid seal and entering the cavity.

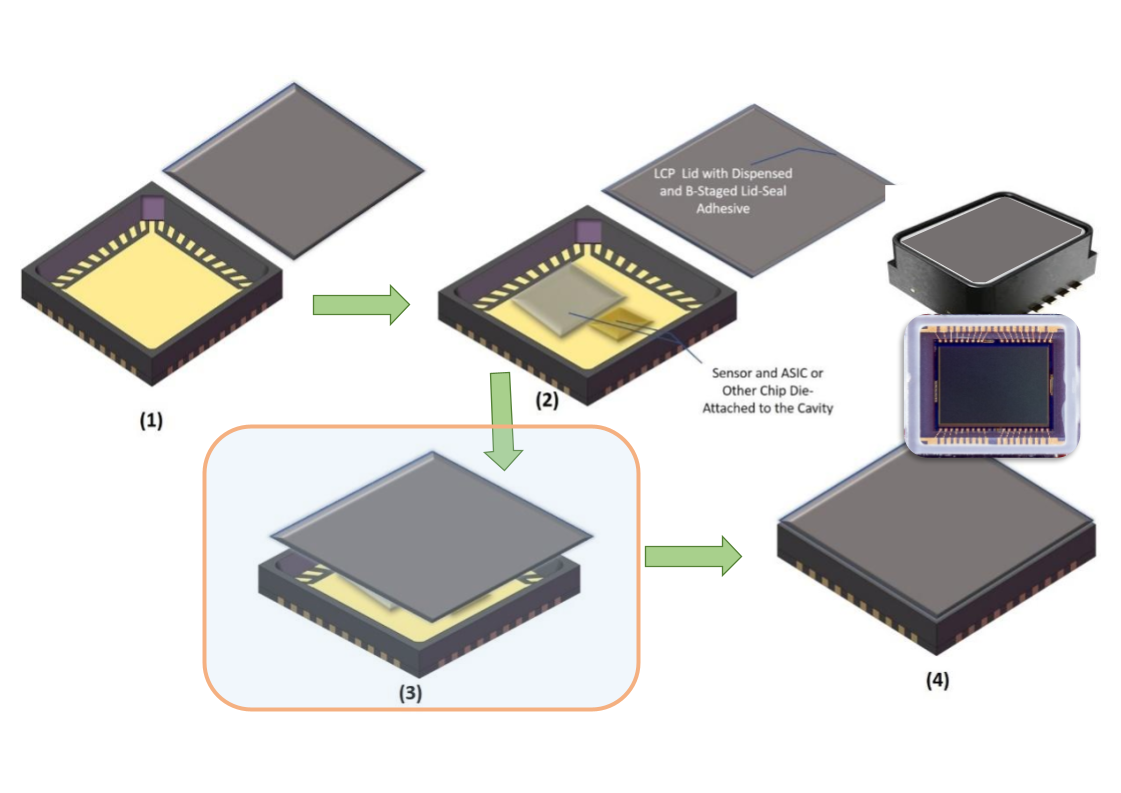

- FLUOROSEAL® is available in dispensable and B-stageable paste for ease of individual cavity packaging. They are also available in B-staged film forms to allow for wafer-level and panel-level cavity packaging. Processing flexibilities are designed for different batch or inline sealing processes.

- FLUOROSEAL® can also be applied both along and outside the lid-seal area to block out moisture and corrosive gases.

- RoHS, REACH, and WEEE compliant to meet UL94V-0 rating.

Reliability for Air Cavity Electronic Packaging Hinged on Lid-Sealing Adhesive and Isothermal Sealing Process with Inert Backfilled Air:

Cavity Electronic Packaging Reliability for Near-Hermetic Packaged Devices Depends both on Lid-Sealing Materials and Lid-Bonding Processing:

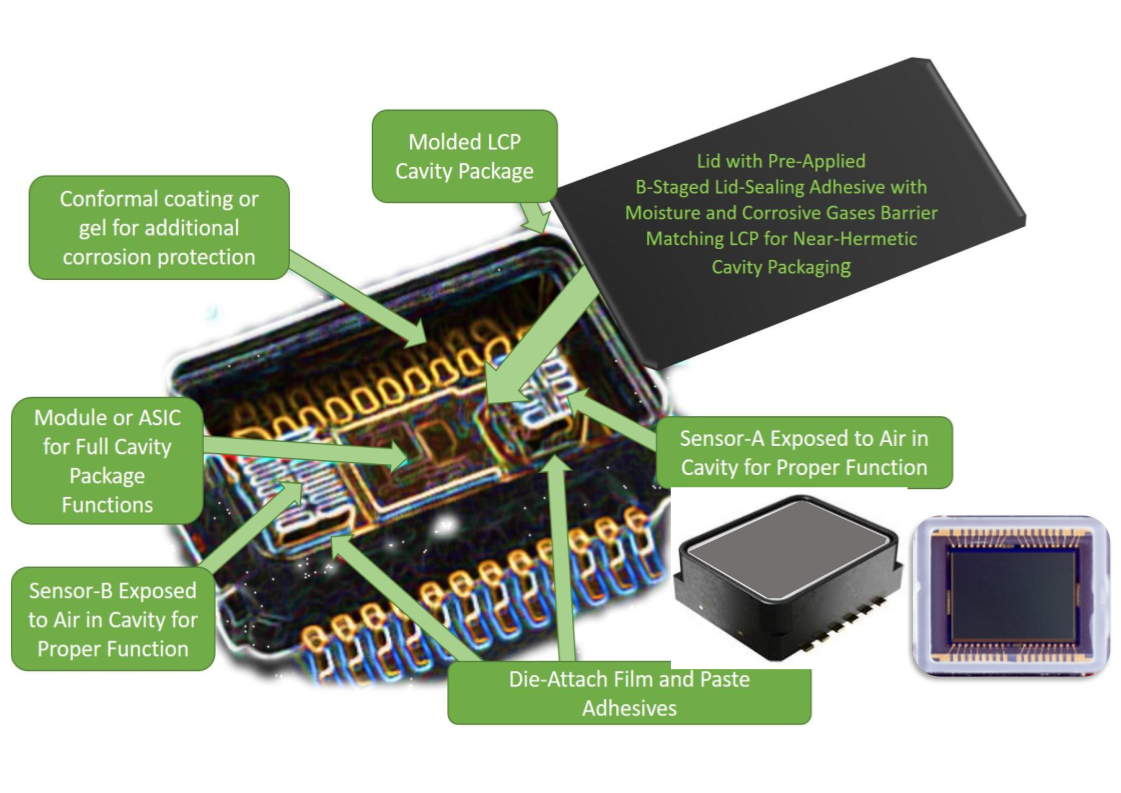

- High moisture barrier molded LCP plastic cavity and lid are important but must also pair with matching moisture barrier lid-sealing adhesive sealant for best long-term reliability.

- Die-Attach film and paste adhesives free of ionic impurities and low moisture absorption accompanied with high moisture barrier conformal coating on exposed circuit traces also added to the reliability.

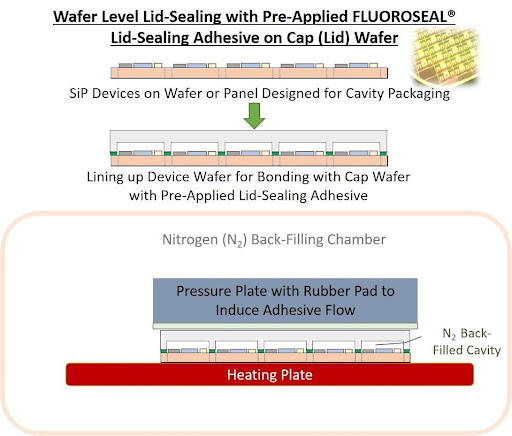

- Designed batch or inline isothermal lid-sealing control with backfilling N2 during the lid-bonding process is critical for pin-hole-free lid-sealing.

- High bond strength and high-temperature moisture barrier lid-sealing adhesive sealant besides keeping the moisture out and backfilled inert N2 inside the cavity packaging.

Reliable Cavity Electronic Packaging with LCP-grade Lid-Sealing Adhesive-Sealant with Matching Moisture and Corrosive Gases Barrier:

Moisture barrier capability depends on molecular structure and is not the same for all lid-seal adhesive and or sealants:

- Epoxy lid-seal is fundamentally an amorphous polymer with relatively high free-space in the adhesive polymer network and has high moisture permeability.

- FLUOROSEAL® is molecularly engineered with high fluorination and low free space to match the best LCP molded package and lid.

- When batch or inline isothermal lid-sealed with backfilling N2 during the lid-bonding process, the cavity formed a high barrier to keep the backfilled N2 and corrosive gases with much larger molecular “kinetic diameter” inside while not allowing the smaller “kinetic diameter” moisture molecules to penetrate the package.

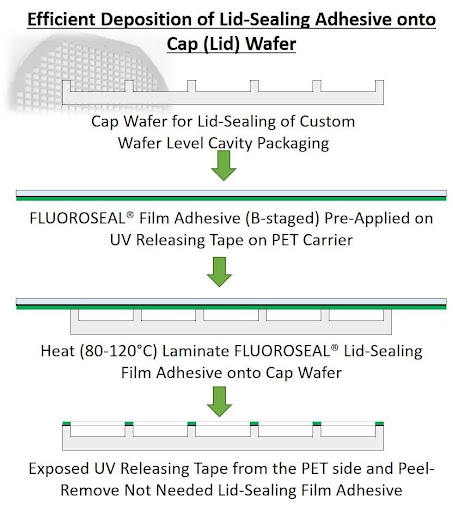

Wafer Scale Cavity Electronic Packaging with Pre-Applied Adhesive on Cap Wafer Blocking Moisture and Corrosive Gases Penetration:

Instead of time-consuming programmable dispensing and B-staging of lid-adhesive on cap-wafer, FLUOROSEAL® adhesive film can be melt-laminated onto cap-wafer and adhesive transferred to lid-rim ready for lid-sealing in wafer level.

Near Hermetic Cavity Electronic Packaging Solutions Beyond Moisture and Corrosive Gases Blocking Lid-Sealing Adhesive:

Moisture and Corrosive Gases Lid-Sealing Barrier with Complementary Die-Attached Film and Paste Adhesives, Conformal Coating, and Lid-Rim Coating-Sealant:

- World’s first UV curing lid-seal FLUOROSEAL® film adhesive that can instantly melt-bond to form lid-sealing in high volume inline production.

- Rim and edge FLUOROSEAL® coating-sealant for large-area devices and large-area optical sensor modules can be applied outside to form a barrier against moisture and corrosive gases.

- High temperature and ionic impurity-free film and paste adhesives for dies and modules.

- FLUOROSEAL® conformal coating offers additional corrosion protection inside the cavity package and devices.