芯片和元件保护。底层填充和球顶封装

芯片保护用的GLOB-TOP和底层填料

Powering Performance for Advanced Electronic Packaging Materials:

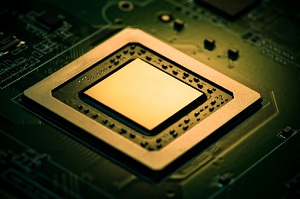

With over 30 years of experience in inventing and formulating specialty adhesives for electronic applications, AI Technology, Inc. (AIT) provides some of the most unique film and paste adhesives, thermal interface materials, encapsulants and coatings for electronic protection and performance requiring extreme reliability. This brochure summarizes AIT’s materials which protect against moisture and related degradation and provide stress absorption and electrical and mechanical protection.

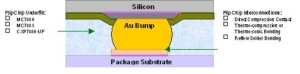

具有超高玻璃化温度的导热倒装材料。

- 经证明,在150°C至300°C的正常温度范围以外的温度下,可使用底层填料和球状填料

- 工程化的分子级应力吸收,为倒装芯片封装提供了无与伦比的可靠性。

- 导热性,使倒装芯片封装的上、下两面的热传递得以实现。

Low Pressure and Low Temperature Molded Encapsulations:

With multiple stack chips and proximity of wire-bonding with sub-mil (<25 microns) gold wire and sub-mil spacing, this type of chip scale packaging requires new type of molding compound to form its protections. Traditional epoxy molding compounds requires high pressure and thus high swiping forces on these gold-wire bonding.

理想中的 "新一代 "芯片封装的理想的 "芯片封装 "包含了创新材料设计和工程化的材料特性中的所有成型复合特性。

- 类似于热固性成型的低压成型参数,比传统环氧树脂成型料的1/10以下。

- 吸湿性和渗透性比传统的成型材料要小得多。

- 膨胀系数(CTE)小于20ppm/°C或低于传统环氧树脂模塑料的膨胀系数。

- 较高的玻璃化温度(Tg)或软化温度,以及

- 由于CTE的差异,模量比传统的材料的模量高得多,可以稳定地减少应力。

The following are a list of the “new generation” of low-pressure molding compounds and encapsulations from the material scientists from AI Technology, Inc.

Low Pressure Molding Compounds and Encapsulations:

| AI Technology部分# | 描写 | 熔体流动,固化,工艺条件 | 模数 (GPa) | CTE (ppm/°C) | Tg (℃) | 介电常数/损耗 (1MHz) | 离子杂质(Na+、K+、Cl-等) |

|---|---|---|---|---|---|---|---|

| MC9883-LPM | Quartz filled Semi-solid mixture Ultra-low CTE | Injection or transfer @40-60°C Curing @ 175°C/10 sec | 8.0 | 16 | 236 | 3.8/0.01 | < 10 ppm |

| MC9885-LPM | Alumina filled Semi-solid mixture Thermally conductive | Injection or transfer @40-60°C Curing @ 175°C/10 sec | 8.0 | 18 | 236 | 4.2/0.01 | < 10 ppm |

应用说明。

- 低压模塑化合物和封装材料在设计上对电子应用中的大多数基材有很强的附着力。所有与固化封装体和成型化合物接触的成型表面都必须涂上脱模涂层,如聚四氟乙烯或有机硅等脱膜剂,以实现脱膜后重复使用。

- Low pressure molding compounds and encapsulations are premixed, deaerated (degassed), and ready for molding without further mixing.

- Transfer of the molding compounds and encapsulations is to perform at temperature below 60°C to ensure long processing time without curing at the transferring chambers.

High Temperature Underfills:

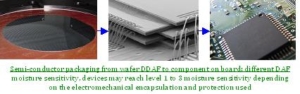

For the traditional flip-chip underfilling, anhydride-based epoxy encapsulation has been successful at least to meet the JEDEC/IPC level 3 of moisture sensitivity. To meet the more stringent level 1 or 2 moisture sensitivity, the underfills must absorb much less moisture to reduce the potential moisture-induced failure.

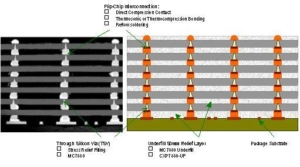

在堆栈芯片应用中,更严格的应力管理和降低对水分的敏感度,如 "通硅孔"(TSV)互连堆栈芯片封装等,更重要的是对堆栈芯片的应用。

AI科技的材料科学家们开发了一系列符合RoHS标准的新一代底片,可承受更高温度的加工和应用。主要的先进特性和功能,下面单独列出了主要的先进特性表。

- 与传统的环氧树脂底层填充物相比,吸湿性和敏感性要低得多。

- 在温度150°C下,固化温度更低,速度更快

- 更高的Tg和模量,以提高应力降低率

- 更低的离子杂质,提高了设备的可靠性。

High Temperature Underfills:

| AI Technology部分# | 描写 | 毛细管-流动,固化,工艺条件 | 模数 (GPa) | CTE (ppm/°C) | Tg (℃) | 介电常数/损耗 (1MHz) | 离子杂质(Na+、K+、Cl-等) |

|---|---|---|---|---|---|---|---|

| UF-MC7883-FP | Quartz filled Liquidous mixture Ultra-low CTE | Capillary flow @ 40-80°C Curing @ 150°C/90 sec | 7.5 | 19 | 236 | 3.8/0.01 | < 10 ppm |

| UF-MC7885-FP | Alumina filled Liquidous mixture Thermally conductive | Capillary flow @40-80°C Curing @ 150°C/90 sec | 7.5 | 20 | 236 | 4.2/0.01 | < 10 ppm |

应用说明。

- 高温下填土要分装在芯片相邻的两面上。

- 在150-200°C的温度下固化后,40-60°C的温度下,毛细管流动作用得到增强。

欲了解更多信息和推荐帮助,请联系AI Technology销售和工程部。

AIT technical sales and service department can also be reached at: 1-609-799-9388 or and Fax: 609-799-9308.