激光脱粘,高Tg,临时粘接解决方案

Focused laser debonding for separating device wafer from the glass carrier is the existing predominant method in the use of temporary bonding adhesive that has high Tg and modulus.

To maximize throughput for wafer processing with high strength temporary bonding, AI Technology, Inc. engineered innovative polymer structures for the WPA-LD product series:

- High Tg of 240ºC

- Low melt-lamination temperature < 150ºC

WPA-LD, unlike typical high Tg and high modulus temporary bonding material, has:

- Great compliance

- Easy residual removal with solvent

AIT’s Next Generation of De-Bondable Products:

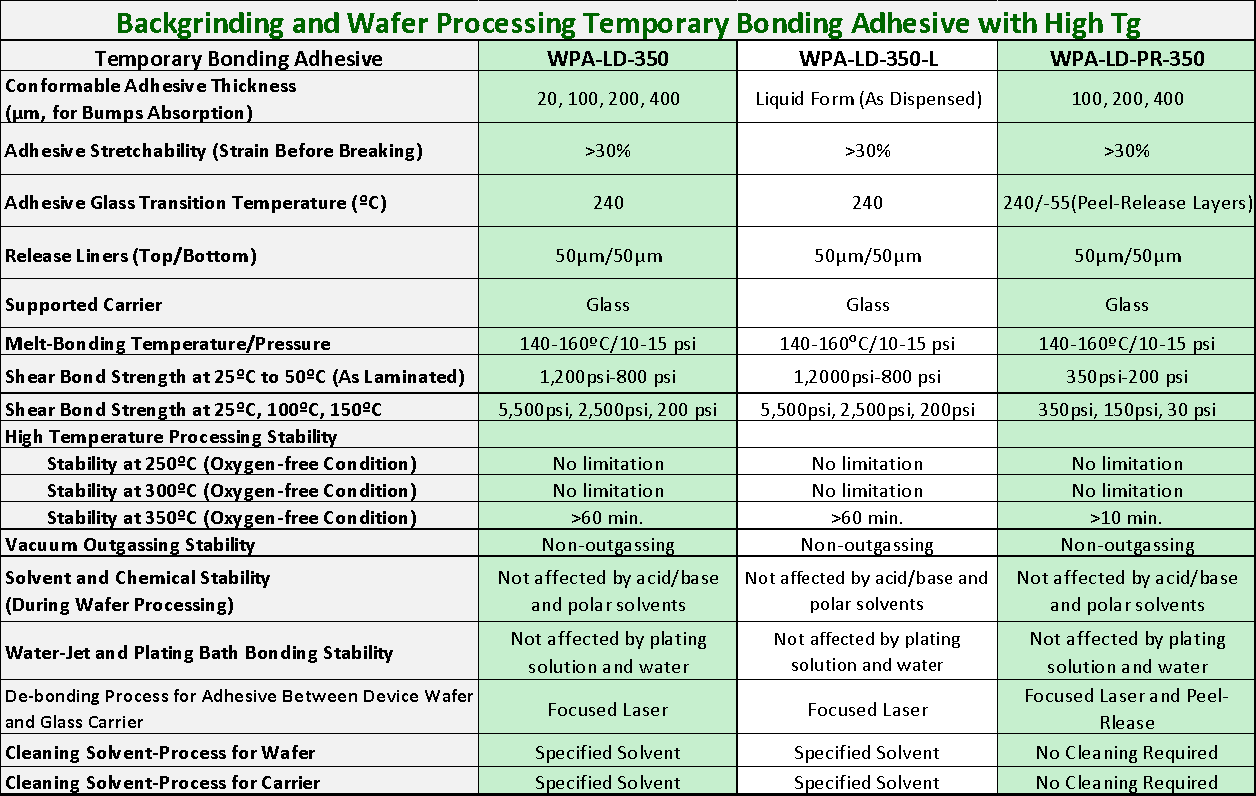

All of these three adhesive solutions maintain high mechanical stability and high thermal stability for wafer processing at least up to 350ºC even in an oxidizing environment

WPA-LD-350: Novel Temporary Bonding Film Adhesive

- Adhesive based on modified cyanate ester polymer

- Tg of 240ºC

- Designed for use with a glass carrier for ease of focused laser de-bonding.

WPA-LD-350-L: Liquid dispensable version of WPA-LD-350

- Apply and B-stage on the device wafer to form film adhesive and heat laminate with glass carrier.

WPA-LD-PR-350: Innovative Laser-and-peel-clean temporary film adhesive

- AIT’s laser debonding WPA-LD-350 with a 10µm thin layer of coating of AIT’s clean peel-release WPA-PRCL-350 on both sides

- To separate device wafer and glass carrier a focused laser can be used

- After separation, simply peel the remaining film from both the device wafer and glass carrier. No residuals, no cleaning required

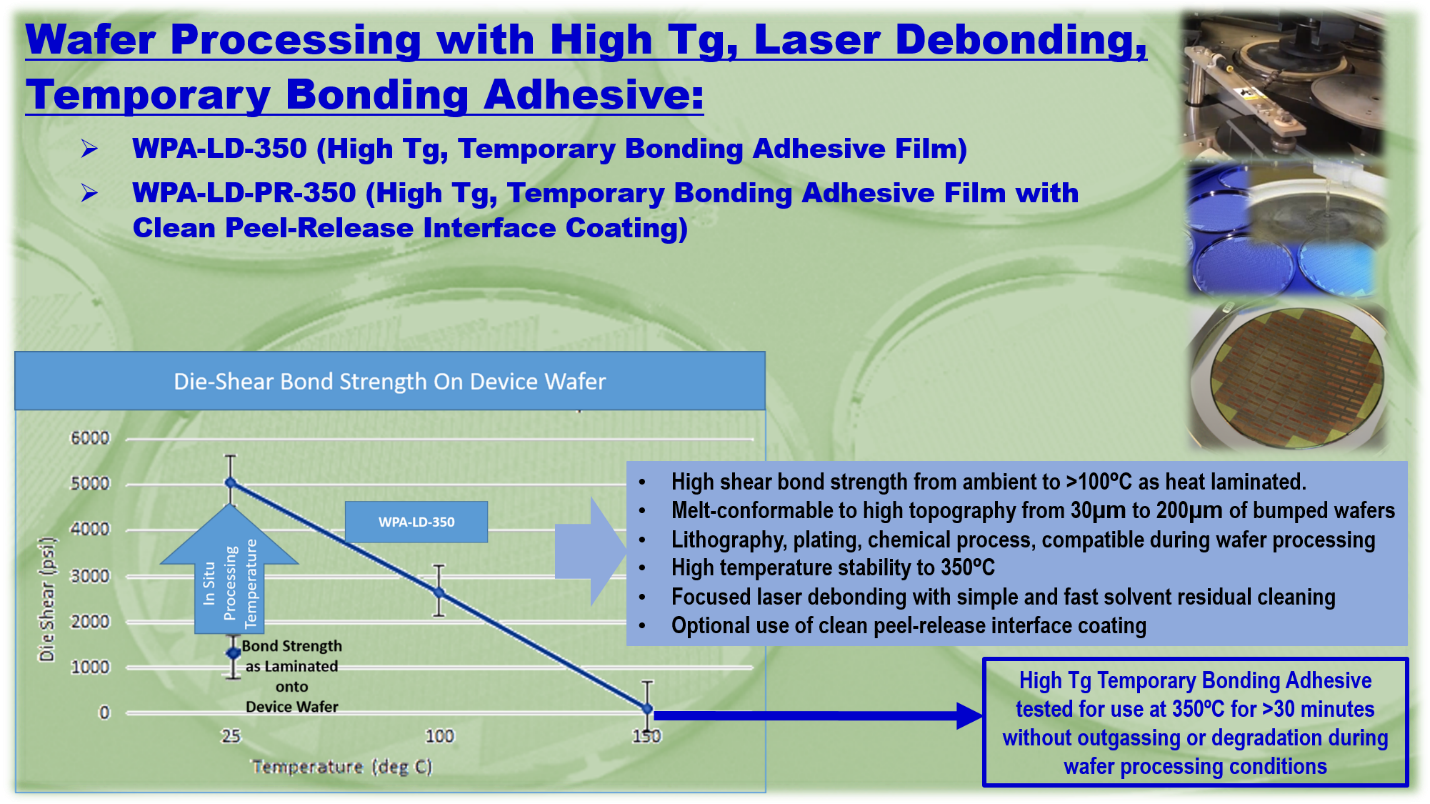

When melt-laminated onto the active side of the device wafer, WPA-LD-350 has the high shear bond strength for vigorous backgrinding and polishing operation. In the subsequent wafer processing exposure of high temperature, the shear strength increases further and yet maintain thermoplastic compliance. This novel temporary bonding adhesive can be easily ablated with focused laser method for separation between the device wafer and the glass carrier. The residual layer can be rapidly removed with designed solvent mixture at ambient or slightly elevated temperature of less than 80ºC.

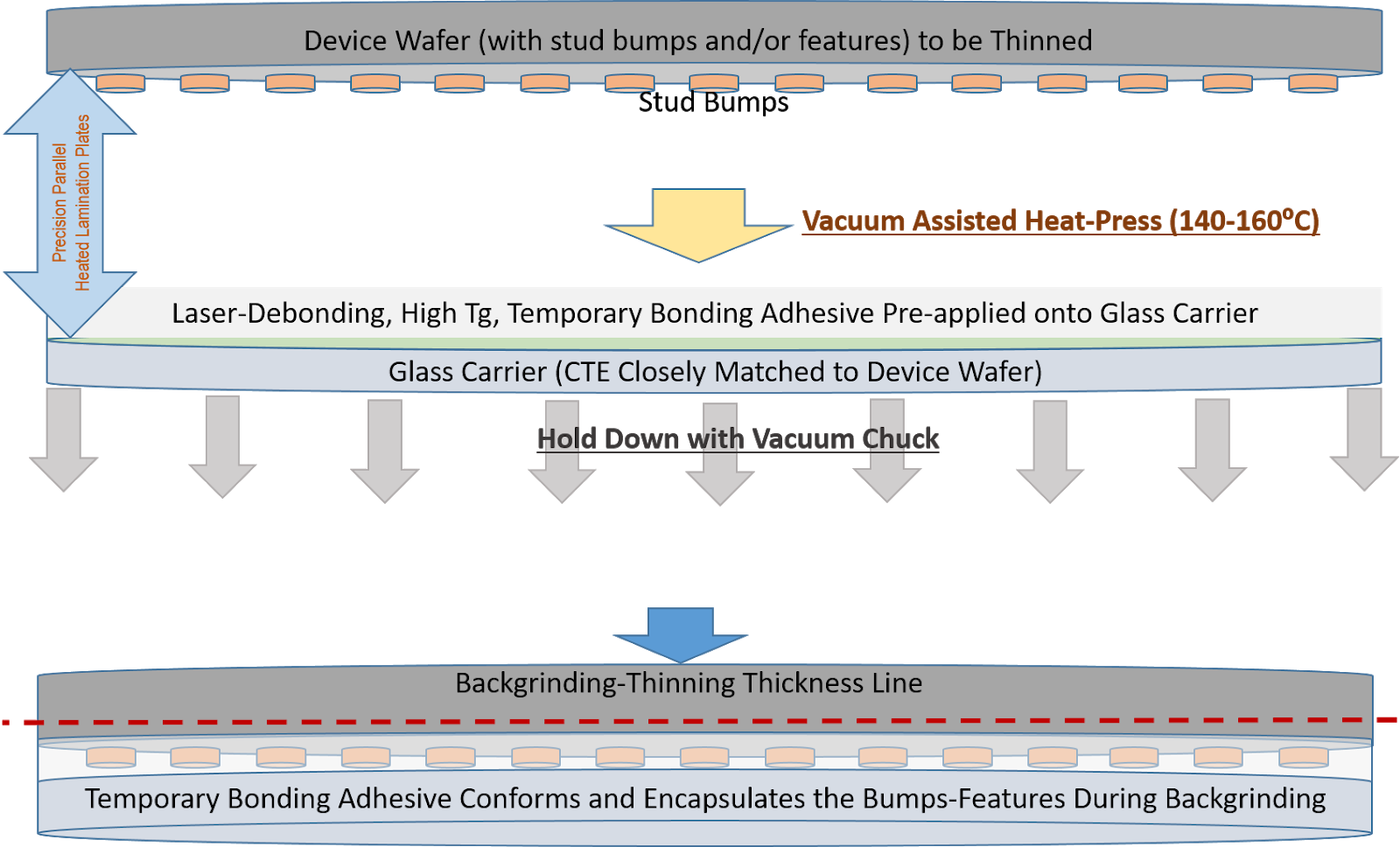

Wafer Lamination Processes with High Tg Temporary Bonding Adhesive:

Film format temporary bonding adhesive from AIT is an improvement from standard materials. This format increases throughput by eliminating intensive film forming processing.

AIT’s WPA-LD adhesive film products may be melt-laminated with temperature from 140 to 160C. Please see the infographic below.

WPA-LD-350 is available with a film thickness of 20µm, 100µm, 200µm, and 400µm for use with any wafer or panel topography.

WPA-LD-PR-350 is available with a film thickness of 100µm, 200µm, and 400µm for use on bumped wafers and panels.

For those with a preference or setup for liquid dispensable products, WPA-LD-350-L is dispensed and b-staged to a film format.

Lamination process for high Tg WPA-LD materials. Glass carrier is used to support the backgrinding and wafer processing to minimize any warpage induced during high-temperature processing. Even with Tg as high as 240ºC, WPA-LD-350 is highly conformable when melt-laminated at 140ºC to 160ºC.

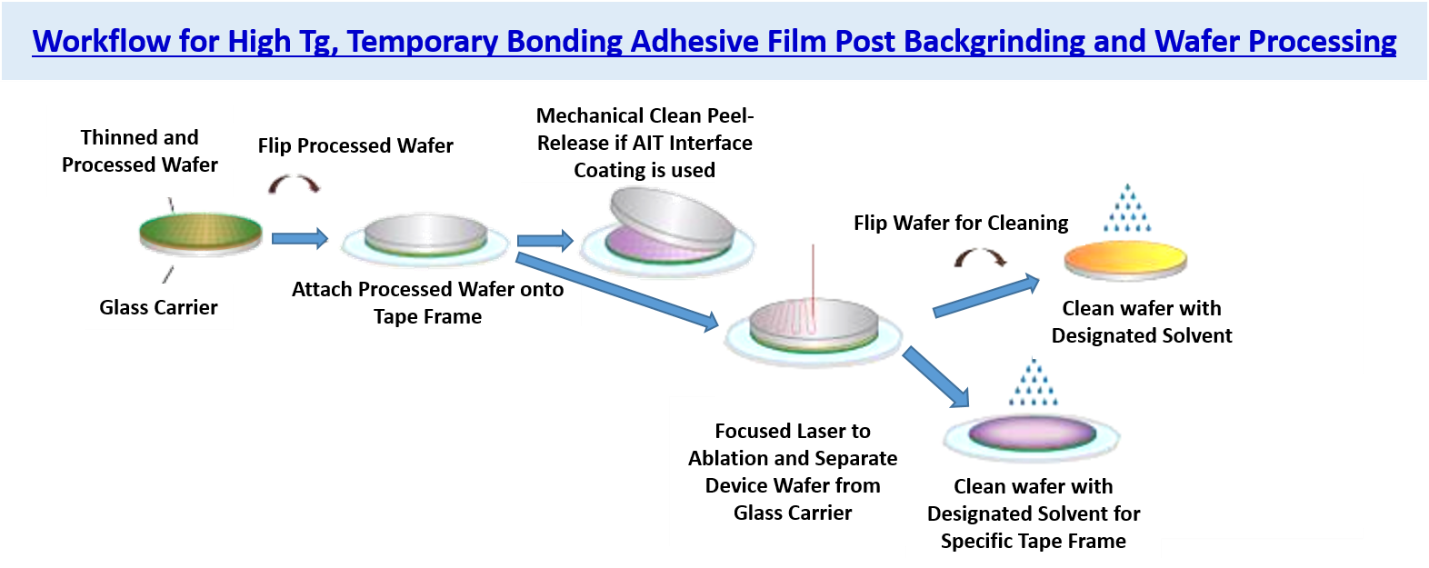

Workflow for Debonding and Cleaning:

The debonding processes are similar to typical focused laser debonding of high Tg temporary bonding adhesive. The solvent removal of residual adhesive with the designated user-friendly solvent solution is within minutes at a temperature less than 80ºC.

The novel high Tg WPA-LD-350 ablated with a focused laser. The temporary bonding adhesive residual stayed on the device wafer side and glass carrier will release clean upon soaking in the designed solvent solution. For WPA-LD-PR-350 with clean peel-release interfaces layer between the device wafer and glass carrier, they may be separated with initiation with stress concentration peel release process. Alternatively, they can be first separated by focused laser ablation and clean peel-release from the device wafer and glass carrier.

Detailed High Tg Temporary Bonding Adhesives:

The following table describes the key properties and processing recommendations for WAP-LT-350 and WPA-LT-PR-350 that incorporated an additional clean peel-release interface layer.