Hyper-conductive Coating for Component Level EMI/RFI Shielding

90dB+ EMI Shielding Effectiveness from MHz to Millimeter GHz at <10-micron Coating Thickness

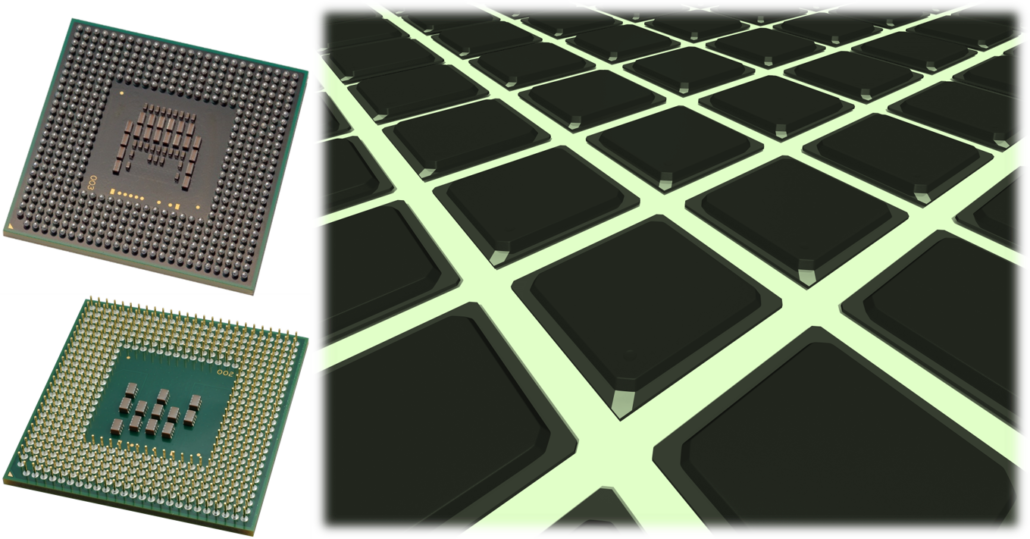

With more than 35 years in providing EMI shielding coatings and sealants, AIT is launching its hyper-conductive coating for component level EMI shielding for 5G devices. EMC8660 at 4-8 micron cured thickness provides more than 90 dB shielding effectiveness from MHz to GHz and millimeter wave EMI/RFI. If necessary, thicker coating to 110dB shielding can be achieved with this AIT package level conformal hyper-conductive coating.

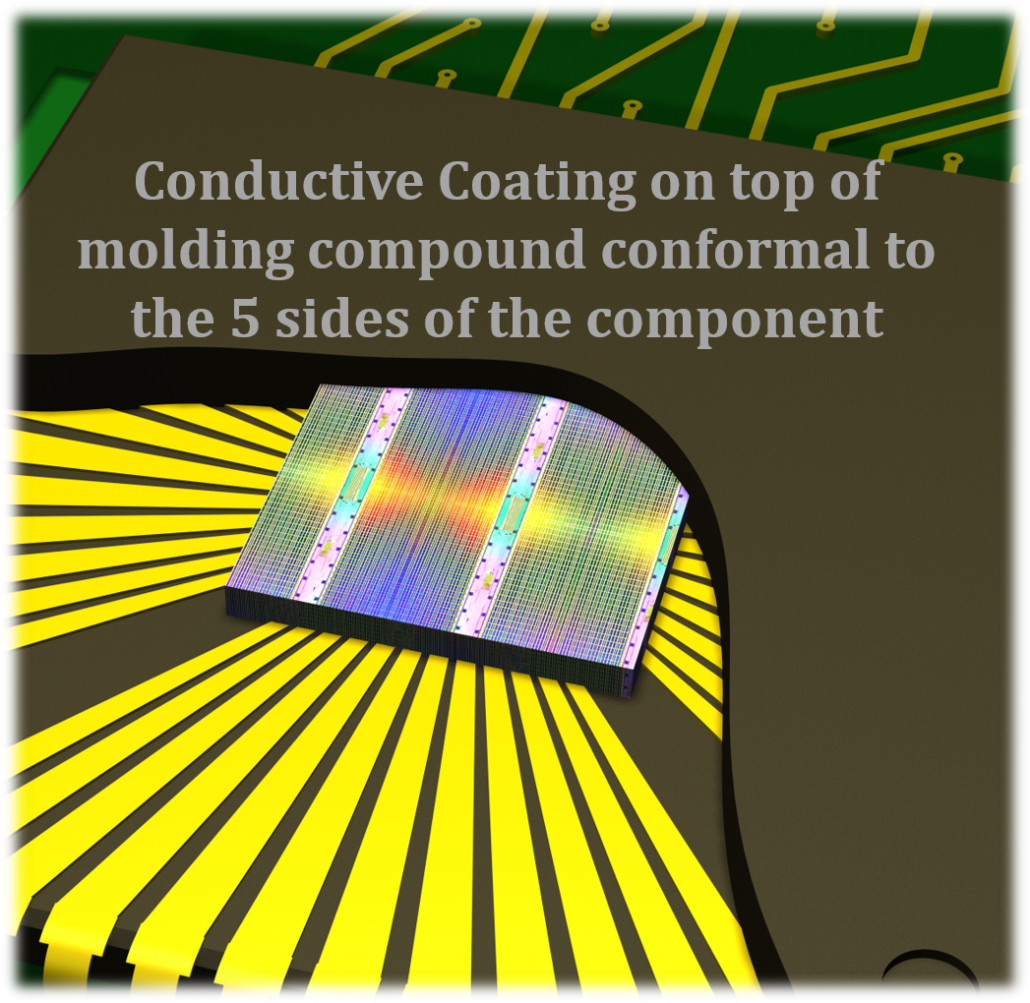

Hyper-conductive EMI Shielding with Complementary Supporting Materials for Precision Coating on 5-Sides of the Components

High frequency mobile devices from 3G to 4G with components much closers and generating signals and electromagnetic radiation that affects each other’s processing or interference. With the advances of 5G and the coming 6G cellular and wireless Internet communication that operates at 6GHz and higher, the need of effective RF electromagnetic interference (RFI/EMI) shielding between the devices onboard of the cellular, computer and communication devices that have high shielding effectiveness, cost effective and spacing saving becomes more demanding.

EMC 8660 is designed to be precision coated and cured onto components ready for direct mounting and soldering at board level. These advanced hyper-conductive coating yield the required high shielding effective for the 4G and 5G cellular products.

Component Package Level Conductive Spray Coating Requires a Sealing Pad for Protection and Handling

In order to completely covering all 5 sides without affecting contact interconnection interface surface, precision jet-spray of the conductive coating must provide precision coating without sipping. The solder balls and contact pins on interconnection interface side must be sealed off from jet-spray coating.

AIT provides complementary component package supporting conformable carrier material that will “absorb” the interconnection studs or solder balls that can be heat release easily after the curing temperature and process for the epoxy-based conductive coating. Needs a conformable sealing pad allowing the package solder balls and pins submerged.

- AIT HRP-100M and HRP-450M are 100-micron and 450-micron thickness conformable supporting carriers for stud bumped and BGA packages respectively.

- These conformable supporting carriers withstand coating curing at temperature up to 175°C. The adhesion strength dropped after curing temperature and process. The component package can be easily picked for board attachment.

EMC8660 component package level EMI conductive coating is epoxy-based that are pre-coated onto the components and cured completely to provide proven performance of over 90 dB EMI/RFI shielding effectiveness from MHz to GHz. The components having solder balls or interconnection pins must be protected during the spray coating process. AIT HRP-100M and HRP-450M are 100-micron and 450-micron pads with thickness conformable supporting carriers for stud bumped and BGA packages respectively. These conformable supporting carriers withstand coating curing at temperature up to 175°C. The adhesion strength dropped after curing temperature and process. The component package can be easily picked for board attachment.

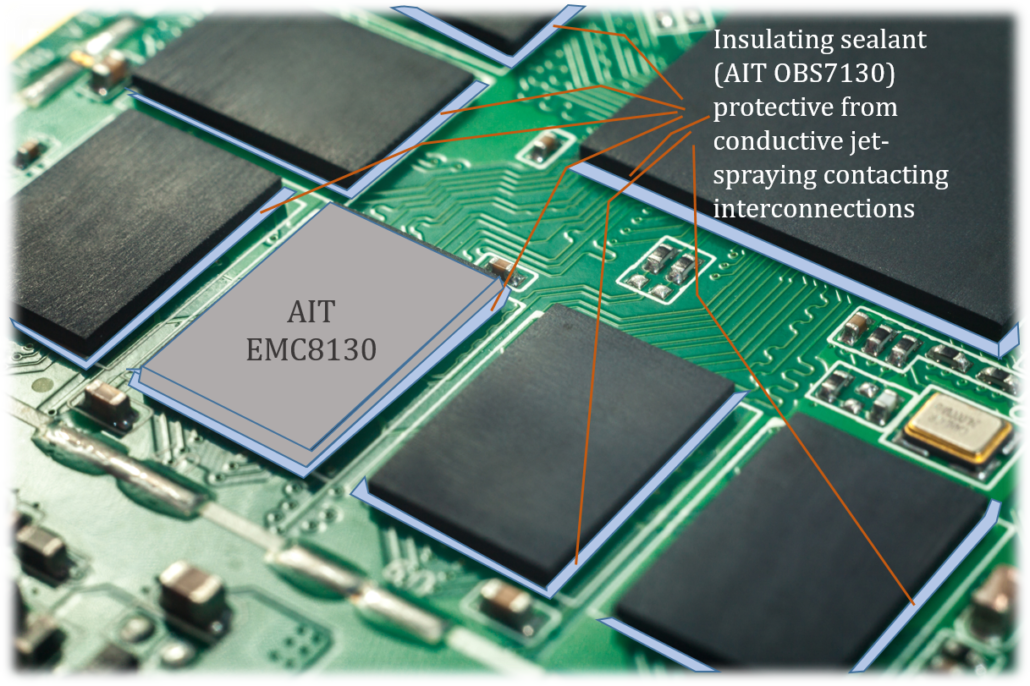

Remedial Jet-Spray conductive coating onto onboard compound

In case of the components with conductive coating have been soldered onto a finished board and yet having interference from EMI, AIT are not adequate in providing required EMI shielding effectiveness, AIT EMC8130 is designed to provide remedial shielding. AIT EMC8130 provides additional shielding effectiveness with additional coating in covering all 5 sides without affecting contact interconnection interface surface and nearby board areas.

In order not to affect components nearby and the underlining interconnections of the components needing extra shielding effectiveness, solder balls and contact pins on interconnection interface side must be sealed off from jet-spray coating. AIT provides a component package-edge insulation protection barrier seal (OBS7130) that can be dispensed onto all 4 sides component package edges as sealant to prevent from coating sipping into contacting with solder balls and pins. OBS7130 is a sealant capable to withstand all board level functional testing without negatively affecting its performance. In fact, both EMC8130 and sealant OBS7130 also have additional protective properties that enhances the protection against moisture, acid rain laden moisture, salt-fog moisture and other negative impact environment.

EMC8130 applied to onboard level component packages for proven performance of over 90 dB EMI/RFI shielding effectiveness from MHz to GHz. SC7130-UVB been designed for large industrial applications. It is packaged in ready to use bottle. It is 1-part air-dry liquid coating without need for additional mixing. Onboard component package edge insulation protection moisture barrier seal (OBS7130) is first dispensed on edges of the components that may be affected by the precision spraying of conductive coating.

Downloads

Advanced Conductive Epoxy Coating Building On Over AIT’s 35 years of EMI shielding Experience

With over 35 years in providing EMI/RFI shielding coating and sealant to military electronics, AIT has one of the most extensive experience in providing these component package level shielding applications.

For an application assistance: https://www.aitechnology.com/analysis/