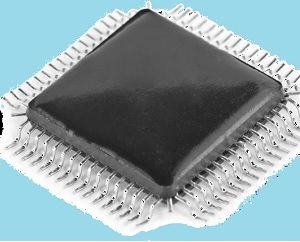

GLOB-TOP MATERIALS FOR CHIP-ON-BOARD (COB) CHIP PROTECTION

WITH SECOND GENERATION OF MODIFIED EPOXY COMPOUNDS

传统的底层填充和球顶材料与酸酐环氧树脂的Tg约为100-150°C,在250°C回流焊接时,可能会产生过高的界面拉伸应力。新一代的AIT底层填充材料和球顶化合物具有不同的化学成分,可以在240℃的超高Tg下实现新的性能。°AI科技的封装产品采用了高热传导率和低热界面电阻,可为倒装芯片封装的顶部和底部的热量传递提供动力。请点击这里查看视频,了解AI科技的底层填充和球顶封装产品如何助力倒装芯片和板载芯片实现更高性能的详细信息。

Properties of Lid-Seal Adhesives and Glob-Top Encapsulants

| PROPERTY | MC7865-GT (Glob-Top Encapsulant) | MC7685-GTS(Glob-Top Encapsulant) | LESP7670-HF (ESP7670-HF) (Lid-Sealing) | LRTK7660-HF (RTK7660-HF) (Lid-Sealing) |

| Electrical Resistivity | >2X1014 Ω-cm | >2X1014 Ω-cm | >5X1014 Ω-cm | >2X1015 Ω-cm |

| Viscosity @5.0 rpm /Thixotropic Index | 60,000 cps/2.5 | 60,000 cps/2.5 | 65,000 cps/4.0 | 65,000 cps/4.0 |

| Material Form Factors | Syringe and Frozen Storage | Syringe and Frozen Storage | B-Stageable at 50-70°C to dry preform | B-Stageable at 50-70°C to tacky preform |

| Customizable Parameters | Viscosity and Thixotropic Index | Viscosity and Thixotropic Index | Conductive and/or Thermally Conductive | Conductive and/or Thermally Conductive |

| 玻璃转化温度Tg (°C) | 240 | 175 | 130 | 165 |

| Device Push-off Strength (psi) | >3500 | >4000 | >3000 | >4000 |

| Hardness (Type) | ~ 90D | ~ 90D | ~ 90D | ~ 85D |

| Cured Density of Conductive Adhesive Portion (gm/cc) | 2.5 | 2.5 | 1.6 | 1.6 |

| Thermal Conductivity | > 2.0 W/m-°K | > 1.8 W/m-°K | > 0.20 W/m-°K | > 0.20 W/m-°K |

| Thermal Expansion Coefficient (ppm/°C) | 18 (X-Y=Z, Isotropic) | 19 (X-Y=Z, Isotropic) | 35 (X-Y=Z, Isotropic) | 35 (X-Y=Z, Isotropic) |

| Maximum Continuous Operation Temperature (°C) | > 250 | > 200 | 150 | 150 |

| Decomposition Temperature @5% weight loss (°C) | >450 | >450 | >450 | >450 |

| Recommended Curing Temperature/Time (°C/min.) | >125/60 | >125/120 | >150/30 | >150/30 |

With the additional dimension of adding high thermal conductivity and low interfacial thermal resistance in the underfill and glob-top compounds, thermal dissipation of components generating heat can be assisted with thermal slug and in case of underfill material for the flip-chip components, heat can be dissipated via the provision at the front side of the flip-chip in additional to the traditional backside of the chip.

欲了解更多信息和推荐帮助,请联系AI Technology销售和工程部。

AI Technology技术销售和服务部门也可以通过以下方式联系:1-609-799-9388或1-800-735-5040 (美国东部时间)和传真:609-799-9308。1-609-799-9388或1-800-735-5040(美国东部时间)和传真:609-799-9308