Reliability for Air Cavity Electronic Packaging Hinged on Lid-Sealing Adhesive Under Controlled Isothermal Sealing Process with Inert Backfilled Air

Cavity Electronic Packaging Reliability for Near-Hermetic Packaged Devices Depends both on Lid-Sealing Materials and Lid-Bonding Processing:

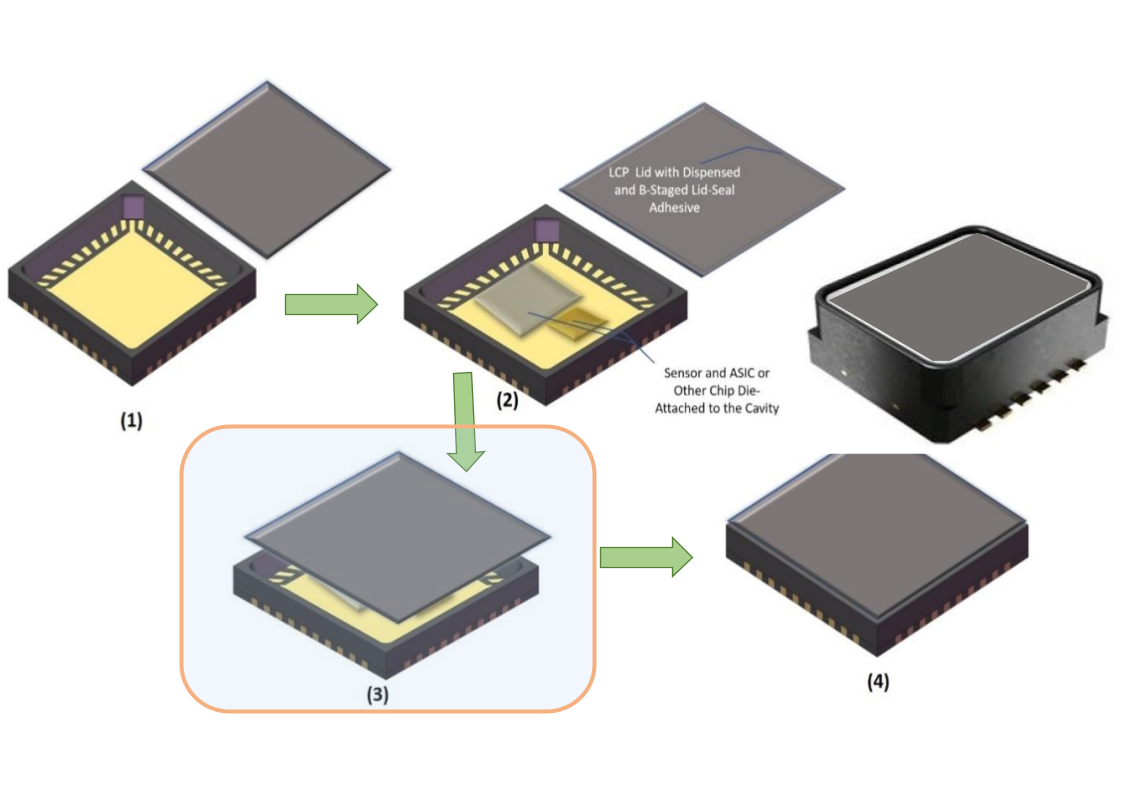

Carefully designed and engineered batch or inline isothermal lid-sealing control with backfilling N2 during the lid-bonding process is critical for pin-hole-free and reliable lid-sealing. The lid-sealed electronic package with fully back-filled N2 or equivalent inert air is at least as important as the high moisture and corrosive gases barrier lid-sealing adhesive. The lid-sealing adhesive ideally should facilitate and provide flexibility in the iso-thermal and pressurized lid-sealing process. The following are some of the lid-sealing material solutions to optimize the cavity electronic packaging reliability:

- High moisture barrier molded LCP plastic cavity and lid are important but must also pair with matching moisture barrier lid-sealing adhesive sealant for best long-term reliability.

- Die-Attach film and paste adhesives free of ionic impurities and low moisture absorption accompanied with high moisture barrier conformal coating on exposed circuit traces also added to the reliability.

- High bond strength and high-temperature moisture barrier lid-sealing adhesive sealant besides keeping the moisture out and backfilled inert N2 inside the cavity packaging.

True Near-Hermetic Lid-Seal Solutions with Designed Work-Flow Friendly Molecular Structure Ideally Suited for High Volume Inline Cavity Electronic Packaging Production:

What distinguishes AIT’s FLUROSEAL® cavity electronic packaging lid-seal adhesive in comparison to the traditional epoxy lid-seal adhesive besides its molecular structure designed to block moisture and corrosive gases from penetration is its production workflow cycle friendly for batch and inline production.

- Dispensable and B-stageable FLUROSEAL® lid-seal adhesives have a long floor life of more than 5 days.

- Easy B-staging at below 60°C to form dry to touch solid adhesive on LCP, metallic, ceramic, or glass lids for ease of handling and pick-and-place lid-placement during production.

- Once B-staged, the lid-seal adhesive is dry and ambient storable for 12 months for ease of shipping and usage.

- Instead of maintaining constant pressure on the lid during the curing cycle for the batch production with the use of traditional B-staged epoxy adhesive, B-staged FLUROSEAL® lid-seal adhesive on lid cover has high “heat melt green strength” to allow releasing placement fixture after initial cycle lid-placement within the isothermal nitrogen backfilled chamber environment. Example of inline workflow for high volume cavity lid-sealing production:

- Preheat the cavity packages without lids in an array fixture plate to 150°C.

- Move the heated fixture plate with cavity packages into a nitrogen backfilled and controlled chamber.

- Pick-and-place lids with B-staged adhesive onto each package with adequate placement pressure of > 5psi to induce adequate adhesive flow.

- Remove the array of cavity packages with lid-seal for completion of curing at 150°C hot stage.