Explore More:

Read More about Die Attach Film here

AIT engineering, sales and service:

1-609-799-9388 or 1-800-735-5040

Fax: 609-799-9308

DAF (Die Attach Film) and DDAF (Dicing Die Attach Film) Adhesives

PROVEN RELIABILITY

Die-Attach film (DAF) adhesive has become popular and mandatory when stack chips are used to accomplish larger capacity in 3-D packaging of flash memory devices. The push now is for even thinner insulating die-attach adhesive that can properly handle interfacial stresses in stacking chips with bond-lines as thin as 8-10 microns or less to help mobile devices to achieve even lower profiles.

In addition to offering a thinner bond-line for stacked chip devices, film adhesives that are properly engineered for die-attach provide several advantages over traditional paste adhesives for almost all semi-conductor devices:

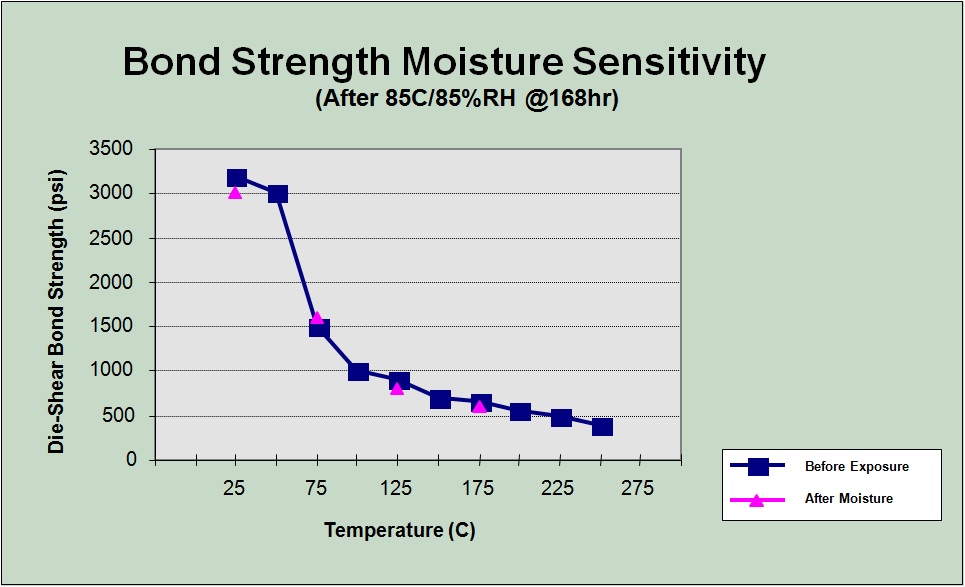

- By eliminating the paste dispensing requirement of low viscosity, AIT produces DAF film adhesives with proper melt-flow and bonding characteristics with engineered molecular structures to manage stress, thermal stability and moisture absorption and sensitivity with unparalleled performance.

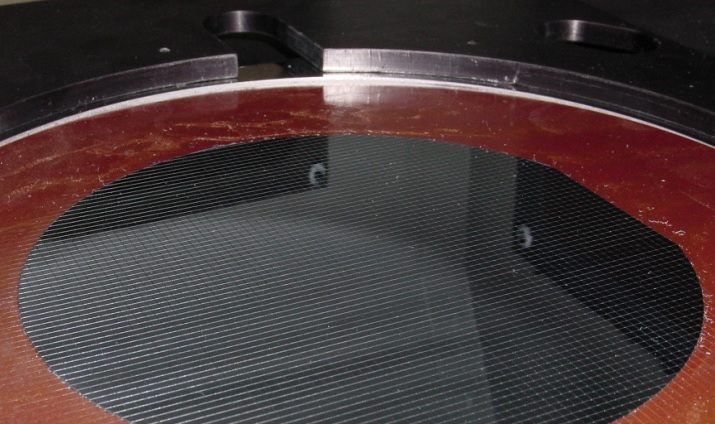

- By laminating the DAF film adhesives with controlled thicknesses from 10 micron, AIT DAF adhesives melt-flow at temperatures around 80°C and are thus ambient storable for shipping and handling for one year at ambient temperature before or after dicing.

- AIT is also one of the first to provide proven DAF adhesives that are electrically conductive for power devices in the thickness of 20 micron.

- AIT is also one of the first to provide thermally conductive DAF adhesives that are electrically insulating but thermally conductive with years of proven successes manufacturing thicknesses of 20 micron.

- AIT DAF is also engineered to melt-flow and bond onto substrates at temperature of 125-175°C with minimal pressure of around 5 psi and continue for full cure at the same temperature without applying pressure. Unlike paste, the die position will not shift, thus allowing ultra precise packaging needed in multi-chip modules (MCM) or SiP (System-in-package).

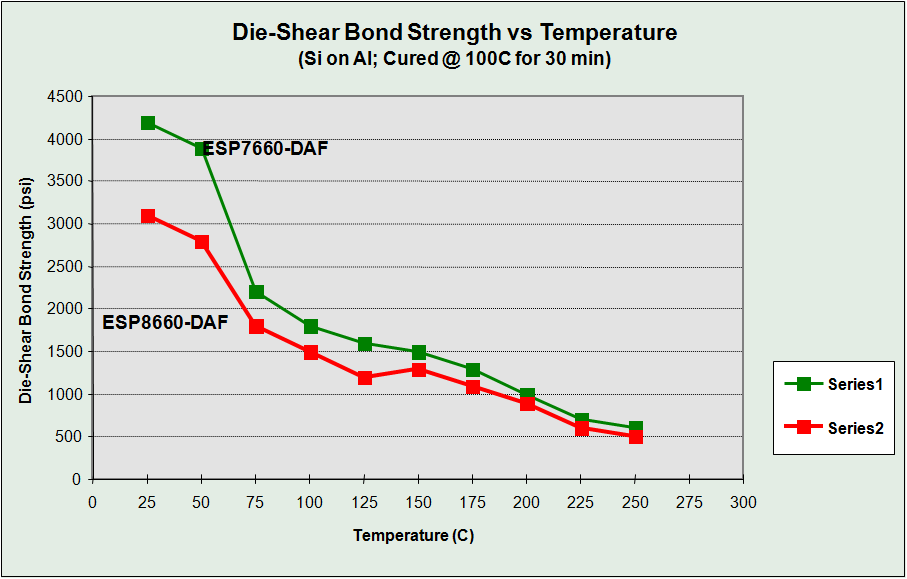

In addition to offering a DAF adhesive with unparalleled performance in managing interfacial stresses even at low bond-line thicknesses, ultra-low moisture-temperature sensitivity, and thermal stability, all with high enough glass transition temperature of 175°C and beyond in enabling high productivity of wire-bonding up to 250°C, AIT DAF adhesives also feature more common properties used in worldwide production:

- RoHS and REACH compliant.

- Availability of width for 450mm and beyond for all thicknesses from 10 micron thickness and with option for pre-laminated onto dicing tape (DDAF) with standard, UV and/or thermal releases.

- Manufactured in clean room environment with scalable capacity of more than 10 million square ft per year in the United States.

Typical Properties of AIT DAF Adhesives

| AIT Product | Characteristics | Electrical Resistivity (ohm-cm) | Thermal Conductivity (Watt/m-oK) | Die-shear (psi) | Tg (oC) | Film Thickness |

| ESP7660-HK-DAF | -Post-curing without fixture and pressure -Meets MIL-STD-883F 5011.4 -Proven reliability for multilayer stack | >1x1014 | >0.8 | >4,000 | 175 | 10 µ 20 µ 40 µ |

| ESP7666-HK-DAF | -Curing without fixture and pressure -Meets MIL-STD-883F 5011.4 -Low thermal resistance + high moisture resistance | >1x1014 | >1.8 | >2,000 | 175 | 20 µ 40 µ |

| ESP8660-HK-DAF | -Curing without fixture and pressure -Low thermal resistance + high moisture resistance -Meets MIL-STD-883F 5011.4 | <4x10-4 | >8.0 | >3,000 | 175 | 20 µ 40 µ |

| ESP8450-DAF | -Optimizing flexibility and strength -Proven for extreme large devices -Meets MIL-STD-883F 5011.4 -Low thermal resistance + high moisture resistance | <4x10-4 | >8.0 | >2,000 | 90 /-50 | 20 µ 40 µ |

| Properties of AIT Flow-Over-Wire (FOW) Die-Attach Film Adhesive | |||||

| AIT Product | Characteristics | Electrical Resistivity (ohm-cm) | Thermal Conductivity (Watt/m-oK) | Die-shear (psi) | Tg (oC) |

| ESP7660-FOW |

| >1x1014 | 0.2 (Unfilled) | >5,000 | 175 |

| ESP7666-FOW |

| >1x1014 | 1.2 (Filled) | >5,000 | 175 |

FLOW-OVER-WIRE (FOW) DIE-ATTACH FILM:

FOW DAF adhesive has an additional processing capability to flow over the wire of the wire-bonded section of the stacked chip. The same process of pre-lamination onto the wafer before dicing is achieved with lower pressure at slightly lower temperature for AIT FOW DAF. The adhesive film behaves more like a liquid adhesive once it reaches the designed temperature of 90-150°C. AIT FOW DAF is engineered with high Tg and molecular stress absorption capability.

![]()

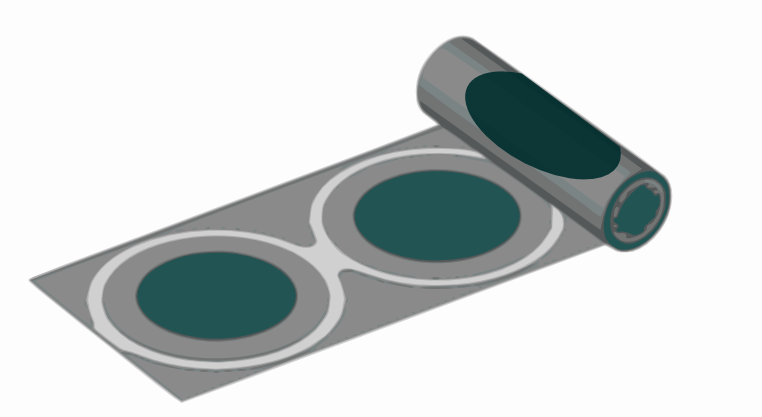

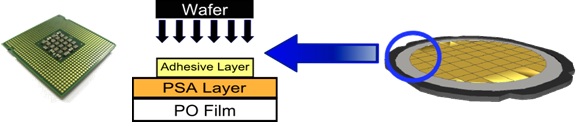

New Dicing Die-Attach Film Availability: AIT is now producing wafer dicing die-attach film in wafer sizes up to 450mm in combination with dicing tape in reel-to-reel format. This made-in-the-USA DDAF and packaging presentation is similar to products by Lintec, Hitachi and other Japanese suppliers.

DICING TAPE FOR DIE-ATTACH FILM ADHESIVES:

AI Technology, Inc. is the only US company that is well known to manufacture its own dicing tapes for wafer dicing in the United States since 2005. While AIT manufactures more traditional controlled peel, UV and heat induced releasing dicing and grinding tapes, one of its pioneering technologies in the controlled peel strength dicing tape application is the availability of tapes that withstand high temperature exposure up to 250°C.

The compatibility of the dicing tapes with the DAF adhesive must be tested and proven before adoption. In this application of dicing tape with die-attach adhesive there are two basic criteria beyond the traditional characteristics:

- It must have good bonding to the DAF and yet can be released without causing part of the DAF to be delaminated from the diced chips.

- The DAF must be free of residuals after the dicing tape is removed.

In addition to not leaving residuals on the DAF on the diced chip, AIT dicing tapes designed for the DDAF application are engineered to blend and form part of the DAF during curing to eliminate all fear of contamination induced failure.

| Properties of AIT Dicing Tapes for DAF Applications | ||||

| AIT Product | Characteristics | Electrical Resistivity (ohm-cm) | Peel Strength(gm-per-inch) | Film Thickness |

| DT-UV1200-SE4 |

| 1x1014 | 100/ 10(Post UV) | PO Base=75µ PSA= 10-15µ |

| DT-CR1000-SE3 |

| 1x1014 | 100 | PO Base=75µ PSA= 10-15µ |

| DT-CR1200-R5 |

| 1x1014 1x105-9 | 100 | AIT Proprietary Base=75µ PSA= 10-15µ |

AIT offers many other Die Attach adhesives not shown on our web site. Please go to Products Application Form to receive a recommendation from our office on your specific application.