Chip & Component Protection: Underfill and Glob-Top Encapsulation

GLOB-TOP and UNDERFILL for CHIP PROTECTION

Powering Performance for Advanced Electronic Packaging Materials:

With over 30 years of experience in inventing and formulating specialty adhesives for electronic applications, AI Technology, Inc. (AIT) provides some of the most unique film and paste adhesives, thermal interface materials, encapsulants and coatings for electronic protection and performance requiring extreme reliability. This brochure summarizes AIT’s materials which protect against moisture and related degradation and provide stress absorption and electrical and mechanical protection.

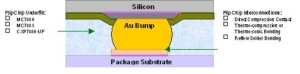

Thermally Conductive Flip-Chip Underfill Materials with Ultra High Glass Transition Temperature:

- Underfills and glob-tops proven to perform at temperatures beyond the normal range of 150°C to as high as 300°C

- Engineered molecular level stress absorption to provide unparalleled reliability in flip-chip packaging

- Thermally conductive to enable thermal transfers from top and bottom sides of the flip-chip packaging

Low Pressure and Low Temperature Molded Encapsulations:

With multiple stack chips and proximity of wire-bonding with sub-mil (<25 microns) gold wire and sub-mil spacing, this type of chip scale packaging requires new type of molding compound to form its protections. Traditional epoxy molding compounds requires high pressure and thus high swiping forces on these gold-wire bonding.

The ideal “new generation” of the chip packaging encapsulation includes all of the molding compound characteristics that are part of the material properties of the innovative material design and engineering:

- Low pressure molding parameter similar to thermoset molding that is 1/10 or less than traditional epoxy molding compounds

- Much less moisture absorption and permeation than traditional molding compound

- Coefficient of expansion (CTE) of less than 20 ppm/°C or lower than traditional epoxy molding compound

- Higher glass transition temperature (Tg) or softening temperature, and

- Much higher modulus than traditional molding compound to provide stable stress reduction due to CTE differences

The following are a list of the “new generation” of low-pressure molding compounds and encapsulations from the material scientists from AI Technology, Inc.

Low Pressure Molding Compounds and Encapsulations:

| AIT Part # | Description | Melt-Flow, Curing, Process Conditions | Modulus (GPa) | CTE (ppm/°C) | Tg (°C) | Dielectric Constant/Loss (1MHz) | Ionic Impurities (Na+, K+, Cl-, etc.) |

|---|---|---|---|---|---|---|---|

| MC9883-LPM | Quartz filled Semi-solid mixture Ultra-low CTE | Injection or transfer @40-60°C Curing @ 175°C/10 sec | 8.0 | 16 | 236 | 3.8/0.01 | < 10 ppm |

| MC9885-LPM | Alumina filled Semi-solid mixture Thermally conductive | Injection or transfer @40-60°C Curing @ 175°C/10 sec | 8.0 | 18 | 236 | 4.2/0.01 | < 10 ppm |

Application Notes:

- Low pressure molding compounds and encapsulations are designed to have strong adhesion to most substrates used in electronic applications. All molding surfaces in contact with the curing encapsulations and molding compounds must be coated with release coating such as PTFE or silicone for releasing for multiple uses.

- Low pressure molding compounds and encapsulations are premixed, deaerated (degassed), and ready for molding without further mixing.

- Transfer of the molding compounds and encapsulations is to perform at temperature below 60°C to ensure long processing time without curing at the transferring chambers.

High Temperature Underfills:

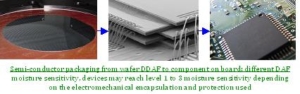

For the traditional flip-chip underfilling, anhydride-based epoxy encapsulation has been successful at least to meet the JEDEC/IPC level 3 of moisture sensitivity. To meet the more stringent level 1 or 2 moisture sensitivity, the underfills must absorb much less moisture to reduce the potential moisture-induced failure.

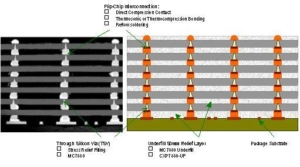

More stringent stress management and reduction of moisture sensitivity are more important in the stack chip applications such as “through silicon vias” (TSV) interconnected stack chip packages.

AI Technology material scientists have developed a series of new generation underfills that withstand RoHS compliant higher temperature processing and applications. The main advanced features and functions are listed below alone with the table of characteristics:

- Much lower moisture absorption and sensitivity than traditional epoxy underfills

- Lower and faster curing at relatively low temperatures of 150°C

- Higher Tg and modulus to enhance stress reduction

- Lower ionic impurities for even higher device reliability

High Temperature Underfills:

| AIT Part # | Description | Capillary-Flow, Curing, Process Conditions | Modulus (GPa) | CTE (ppm/°C) | Tg (°C) | Dielectric Constant/Loss (1MHz) | Ionic Impurities (Na+, K+, Cl-, etc.) |

|---|---|---|---|---|---|---|---|

| UF-MC7883-FP | Quartz filled Liquidous mixture Ultra-low CTE | Capillary flow @ 40-80°C Curing @ 150°C/90 sec | 7.5 | 19 | 236 | 3.8/0.01 | < 10 ppm |

| UF-MC7885-FP | Alumina filled Liquidous mixture Thermally conductive | Capillary flow @40-80°C Curing @ 150°C/90 sec | 7.5 | 20 | 236 | 4.2/0.01 | < 10 ppm |

Application Notes:

- High temperature underfill is to be dispensed onto two adjacent sides of the chip to be underfill.

- Enhanced capillary flow action with temperatures of 40-60°C following with curing at temperatures of 150-200°C.

For more information and recommendation assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or and Fax: 609-799-9308.